-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

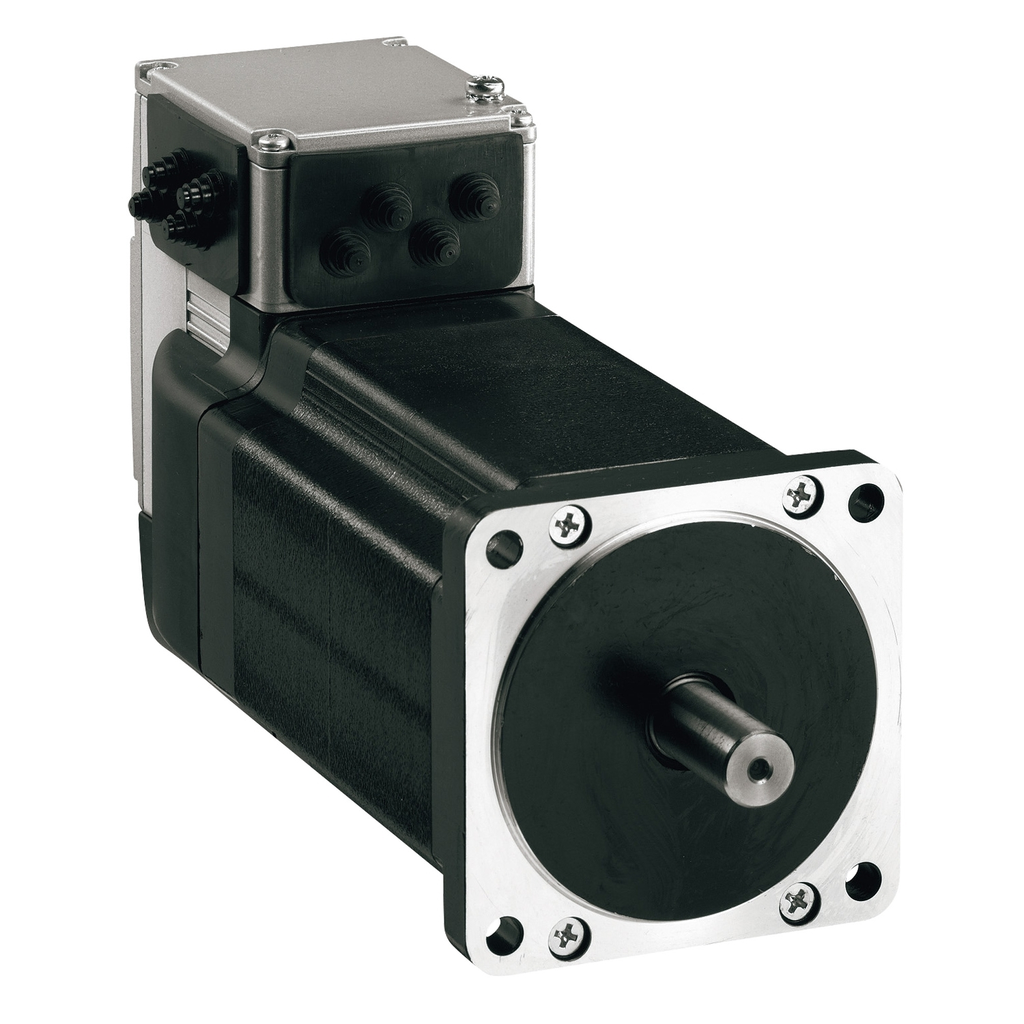

integrated drive ILS with stepper motor - 24..48 V - EtherNet/IP - 5 A

INTEGRATED DRIVE ILS WITH STEP

SQDILS2K852PB1A0

ILS2K852PB1A0

3606485204970

1758.89

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-integrated-drive-ILS-with-stepper-motor-24-48-V-EtherNet-IP-5-A-3606485204970

- Shaft Diameter: 12 mm

- Shaft End: Untapped

- Shaft Length: 30 mm

- Warranty Length: 18 mth

- oc_Ref=Lexium_ILS_EU_CE_DoC&p_File_name=LAH2015001.05_DeclarationOfConformity_ILA_ILE_ILS_signed.pdf(Download)

- H2015001_05_DoC_ILA_ILE_ILS&p_File_name=LAH2015001.05_DeclarationOfConformity_ILA_ILE_ILS_signed.pdf(Download)

- cbedd3a9c8d5011d1aa4e97f82f8f6cbae52514bILS2K852PB1A0(Download)

- 675d9bdfe10157e96feb22619751f8827de57f0aENVEOLI1411002EN_V2.pdf(Download)

- 0382daad692452ae4a7a3c2831599c78396be37cBU_AUT_2228_EPDS_V_01_EN.zip(Download)

- 6b4d3e1aabb7f8b60e92f3cb17a931cb8f9e71f0files?p_Doc_Ref=MCADID0000602_3D-CAD(Download)

- 51ca24e0fd01df6ee3e95cc4fa2e2380fb53fcaefiles?p_Doc_Ref=DIA7ED2110701EN(Download)

- 642f527e5af702165113e5227eecafba96f47972files?p_Doc_Ref=DIA7ED2110701EN-US(Download)

- ecff48df685712886da7863947affcf772d87768files?p_Doc_Ref=0198441113682(Download)

- b7affb6c2eff9375d1f4b207b77cf4ce7de9218bENVPEP1411002EN_V2.pdf(Download)

- Features

- Specifications

- Prop 65

- WARNING: This product can expose you to chemicals including: Lead and lead compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Communications & Management Attributes

- Communication Interface : Ethernet/IP, Integrated

- Physical Attributes

- Motor Flange Size : 85 mm

- Shaft Length : 30 mm

- Complementary Attributes

- Maximum Axial Force FA : 170 N tensile force), 30 N force pressure)

- Maximum Switching Current : 100 mA per output, 200 mA total

- Maximum Mechanical Speed : 3000 rpm

- Maximum Radial Force FR : 100 N

- Important Information Attributes

- Nominal Speed : 180 rpm 24 V, 360 rpm 48 V

- Supply Voltage Description : single phase 24 V DC, single phase 48 V DC

- Carbon Footprint Of The Distribution Phase A4 : 0.5031883853, 0.5 kg CO2 eq.

- Carbon Footprint Of The End Of Life Phase C1 To C4 : 0.4 kg CO2 eq., 0.4186533994

- Carbon Footprint Of The Installation Phase A5 : 0.024347932, 0 kg CO2 eq.

- Carbon Footprint Of The Manufacturing Phase A1 To A3 : 22 kg CO2 eq., 21.5052407932

- Carbon Footprint Of The Use Phase B2 B3 B4 B6 : 603 kg CO2 eq., 602.9272166244

- Local Data Status : Publishable

- Local Publishable Date : 2026-01-12

- Device Type : Motion - integrated drive

- Serviceability : Yes

- Traceability : Yes

- Field Service Division : IDIBS

- Average Life Duration : 15 year(s)

- Legacy WEEE Scope : Out

- Scope Perimeter : At least in Europe

- EOLI Availability Display : Yes

- End Of Life Doc Ref : ENVEOLI1411002EN

- Reach Full Compliance Status : Reference contains Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : CONTAINS_SVHC

- Reach Compliance Directive : Reference contains Substances of Very High Concern above the threshold

- ROHS EUR In Scope : No

- ROHS EUR Status : Compliant with Exemptions

- ROHS EUR Full Compliance Status : Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS EUR Full Compliance Status Id : PRO_ACTIVE_COMPLIANCE

- China ROHS In Scope : Yes

- With Recycled Cardboard : Yes

- Without Single Use Plastic : No

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : N

- WD Status : 5 - INITIALIZED WITH DataSCAN OK (Migration)

- Centring Collar Diameter : 60 mm

- Circle Diameter Of The Mounting Holes : 99 mm

- Coefficient 1 0 : 43.332 N.m

- Coefficient 1 1 : -32.21 N.m/rpm

- Coefficient 1 2 : 8.058 N.m/rpm²

- Coefficient 1 3 : -0.681 N.m/rpm3

- Coefficient 2 0 : -8.544 N.m

- Coefficient 2 1 : 25.388 N.m/rpm

- Coefficient 2 2 : -12.128 N.m/rpm²

- Coefficient 2 3 : 1.603 N.m/rpm3

- Compatibility Code : ILS

- Current Consumption : 5000 mA maximum continuous

- Curve Type : semilog

- Device Short Name : ILS

- Feedback Type : index pulse

- Gear Box Type : without

- Holding Brake : without

- Holding Torque : 4 N.m

- Mounting Holes Diameter : 6.5 mm

- Network Type : DC

- Nominal Torque : 4 N.m

- Package Weight Lbs : 3.9 kg

- Peak Stall Torque : 4 N.m

- Product Availability : Non-Stock - Not normally stocked in distribution facility

- Product Or Component Type : motion integrated drive

- Range Of Product : Lexium integrated drive

- Returnability : No

- Second Shaft : without second shaft end

- Service Life In Hours : 20000 h bearing

- Shaft Diameter : 12 mm

- Shaft End : untapped

- Shock Resistance : 150 m/s² 1000 shocks IEC 60068-2-29

- Sizing Reference : ILS2_852P

- Speed Feedback Resolution : 20000 points/turn

- Sustainable Packaging : No

- Total Lifecycle Carbon Footprint : 625 kg CO2 eq.

- Vibration Resistance : 20 m/s² 10-500 Hz) 10 cycles IEC 60068-2-6

- Voltage 1 : 24 V

- Voltage 1 Speed 1 : 170.586 rpm

- Voltage 1 Speed 1 Max : 170.586 rpm

- Voltage 2 : 48 V

- Voltage 2 Speed 2 : 341.18 rpm

- Voltage 2 Speed 2 Max : 341.18 rpm

- Winding Type : medium speed of rotation and medium torque

- Relationship Type : Compatible relationship

- Pep Code : ENVPEP1411002EN

- Pep Verification Date : 2020-11-01

- PCR Version : PCR-ed3-EN-2015 04 02

- Type Of Verification For The Pep : Independent internal review

- Functional Unit Description : To coordinate and synchronize motion control with stepper, servo or burshless DC motor 70% of the time for 10 years.

- Functional Unit Unit : unit

- Product Kit Identifier : N

- Product Manager : RAIMUND KLINGLER

- Environment Attributes Main

- Ambient Air Temperature For Operation : 40-55 °C (with power derating of 2 % per °C), 0-40 °C (without derating)

- EU ROHS Directive : Compliant By Exemption, Pro-active compliance (Product out of EU RoHS legal scope)

- IP Degree Of Protection : IP41 shaft bushing: conforming to IEC 60034-5, IP54 total except shaft bushing: conforming to IEC 60034-5

- Operating Altitude : <= 3280.84 ft (1000 m) without derating, <= 3280.84 ft (1000 m) without derating

- Permissible Ambient Air Temperature Around The Device : 105 °C power amplifier, 110 °C motor

- ROHS Exemption Information : Yes

- Take Back : No

- Recycled Metal Content At Cr Level : 0 %

- China ROHS Regulation : X

- Mercury Free : Yes

- Carbon Footprint : 625.3786471344

- Circularity Profile : ENVEOLI1411002EN

- Environmental Disclosure : ENVPEP1411002EN

- Packaging Made With Recycled Cardboard : Yes

- Packaging Without Single Use Plastic : No

- Reach Regulation : Reference contains Substances of Very High Concern above the threshold

- Relative Humidity : 15-85 % without condensation

- Pep Code : ENVPEP1411002EN

- Pep Verification Date : 2020-11-01

- PCR Version : PCR-ed3-EN-2015 04 02

- Type Of Verification For The Pep : Independent internal review

- General Attributes

- Product Or Component Type : motion integrated drive

- Range Of Product : Lexium integrated drive

- Contractual Warranty Attributes

- Warranty Period : 18 months

- Warranty : 18 months

- Input Attributes

- Discrete Input Current : 10-10 mA at 24 V safety input, 2-2 mA at 24 V 24 V signal interface