-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

Contactor, TeSys K, 3P, AC-3, lt or eq to 440V, 6A, 1 NC aux, 24VDC coil

CONTACTOR 600VAC 6AMP IEC +OPT

SQDLP1K0601BD

LP1K0601BD

3389110363210

91.85

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-TeSys-K-contactor-3P-AC-3-440-V-6-A-1-NC-aux-24-V-DC-coil-785901832447

- Warranty Length: 18 mth

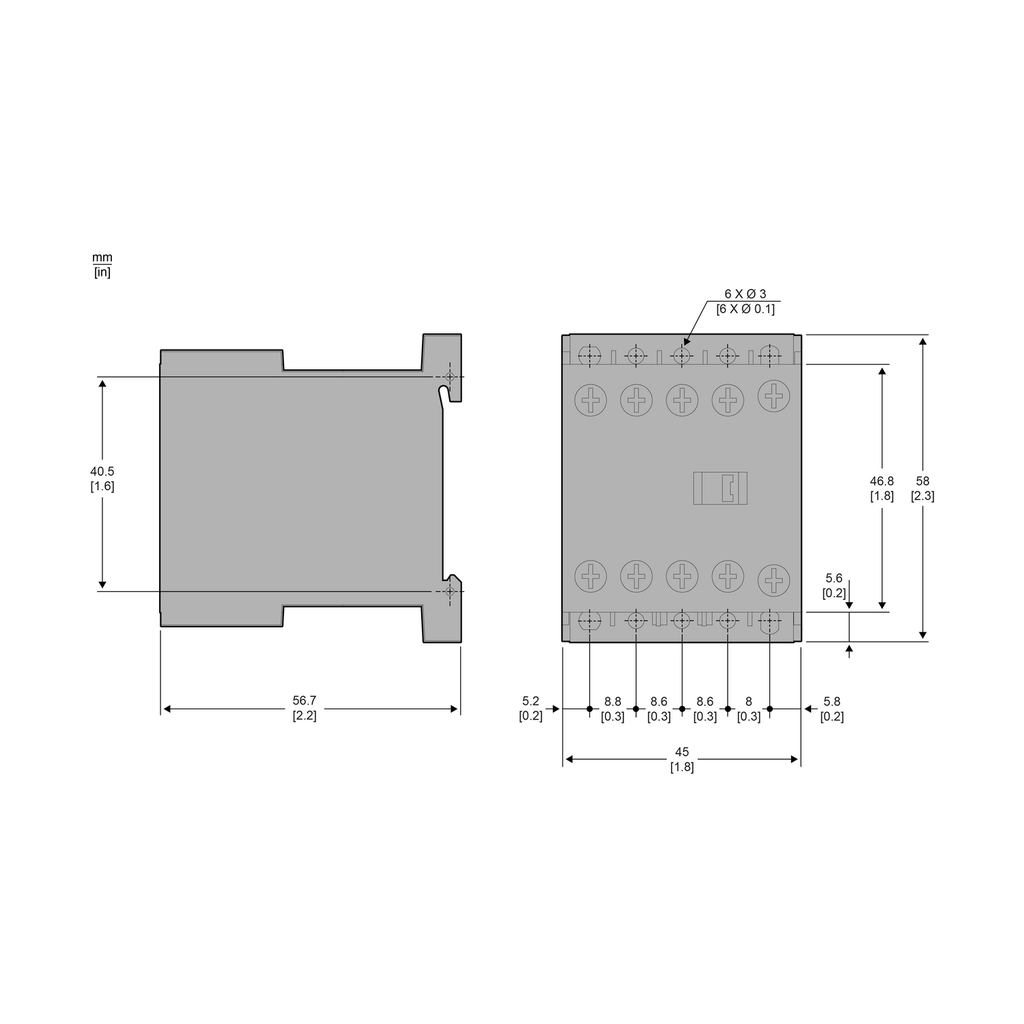

LP1K0601BD is a compact 3-pole TeSys K contactor from Schneider Electric for motor applications. Rated 9A AC-3 4kW@400V, it includes a 24V DC coil and 1NC auxiliary contact allowing easy integration to all control systems. LP1K0601BD is a 3-pole TeSys K contactor from Schneider Electric for simple motor applications rated up to 2.2kW@400V. Very compact, DIN-rail compatible, with connections by screw clamp terminals, it can be easily integrated into all control systems thanks to its 24V DC coil and 1NC built-in auxiliary contact. Available worldwide, it complies with multi-standards (IEC, UL, CSA, CCC, EAC, Marine). Very compact, 45mm wide, for DIN-rail and panel mounting. Ready for connection to all control systems thanks to a 24V DC control voltage and 1NC built-in auxiliary contact. Optimized for simple power applications. Can be completed with auxiliary contact blocks (LA1K, LA2K) and thermal relays (LR2K).

- ITuDz_GqQd8998-22132553_TeSys-K-video(Video)

- 6bfdd98e0e4674f08923files?p_Doc_Ref=MCADPP0003365_3D-CAD&p_File_name=MCADPP0003365_3D-simplified.stp(Download)

- b1b23b3287e589d4bedfiles?p_Doc_Ref=MKTED210011EN&p_File_name=TeSys_Catalog-MKTED210011EN_2025-02.pdf(Download)

- 6986fc5497dfc6e5a8a6f0150faaef67af309977files?p_Doc_Ref=2024010304642075(Download)

- e3b2bb6299b6a69b0db7ca08cc666a81e599ab4fLC.K_LP.K06-16_LV_2024010304627909.pdf(Download)

- 53c326385c359ecd572f8866c213f71a96ae4674LC.K_LP.K_LV_Batam_CN73577.pdf(Download)

- 6a4a234435da7b7cdcf3a576381c12ba8b938f3bCOFC_80272963_EN.pdf(Download)

- b37752cfbdeda2d8b4b117755e7cd258f3fc86d3files?p_Doc_Ref=E164862-19930524(Download)

- a2003d087087f95ff98752eadfiles?p_Doc_Ref=ENVPEP1503003&p_File_name=Internal PEP ENVPEP1503003_V4.pdf(Download)

- 29750f59b96b9277e444b37086949572ead3b9feLP1K0601BD(Download)

- e1ce3dd8c5c604e5e6a4245548d543cfiles?p_Doc_Ref=ENVEOLI1503003&p_File_name=EoLI_ENVEOLI1503003_V4.pdf(Download)

- 9e48c0a8bb7a5039d85051b6cd97e2b6060c520afiles?p_Doc_Ref=EU_DoC_SC16040406(Download)

- 3f72b8e718e8f7eff5c9284c68b5d6a03957de03files?p_Doc_Ref=UKCA_Declaration_SC16040406-UK(Download)

- 1d3a2c790fa8c97b7c696fe56e0a215d06429c35files?p_Doc_Ref=1378085_01A55(Download)

- 64ce96655c01dc502d82960e5136dd8602062150files?p_Doc_Ref=1379131_01A55(Download)

- c8bc63e7d262d1d20f40e7files?p_Doc_Ref=BU_AUT_666_EPDS_V1_M1_EN&p_File_name=BU_AUT_666_EPDS_V1_EN.zip(Download)

- 86d20b73d302d7ebcaf64bff78bc185e85fee368files?p_Doc_Ref=LP1K0601BD_CAD(Download)

- Product Description

- Features

- Specifications

LP1K0601BD is a compact 3-pole TeSys K contactor from Schneider Electric for motor applications. Rated 9A AC-3 4kW@400V, it includes a 24V DC coil and 1NC auxiliary contact allowing easy integration to all control systems. LP1K0601BD is a 3-pole TeSys K contactor from Schneider Electric for simple motor applications rated up to 2.2kW@400V. Very compact, DIN-rail compatible, with connections by screw clamp terminals, it can be easily integrated into all control systems thanks to its 24V DC coil and 1NC built-in auxiliary contact. Available worldwide, it complies with multi-standards (IEC, UL, CSA, CCC, EAC, Marine). Very compact, 45mm wide, for DIN-rail and panel mounting. Ready for connection to all control systems thanks to a 24V DC control voltage and 1NC built-in auxiliary contact. Optimized for simple power applications. Can be completed with auxiliary contact blocks (LA1K, LA2K) and thermal relays (LR2K).

- Prop 65

- WARNING: This product can expose you to chemicals including: Antimony oxide & Antimony trioxide, which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov

- Conformance Attributes

- Standards : EN/IEC 60947-4-1, EN/IEC 60947-5-1, UL 60947-4-1, UL 60947-5-1, CSA C22.2 No 60947-4-1, CSA C22.2 No 60947-5-1, GB/T 14048.4

- Complementary Attributes

- Control Circuit Type : DC standard, DC standard

- Control Circuit Voltage Limits : operational: 0.8...1.15 Uc (at <50 °C), operational: 0.8...1.15 Uc (at <50 °C), operational: 0.8...1.15 Uc (at <50 °C), drop-out: >= 0.10 Uc (at <50 °C), drop-out: >= 0.10 Uc (at <50 °C), drop-out: >= 0.10 Uc (at <50 °C)

- IRMS Rated Making Capacity : 110 A AC for power circuit conforming to IEC 60947, 110 A AC for power circuit conforming to IEC 60947, 110 A AC for power circuit conforming to IEC 60947, 110 A AC for power circuit conforming to IEC 60947, 110 A AC for signalling circuit conforming to IEC 60947, 110 A AC for signalling circuit conforming to IEC 60947, 110 A AC for signalling circuit conforming to IEC 60947, 110 A AC for signalling circuit conforming to IEC 60947

- Minimum Switching Current : 5 mA for signalling circuit, 5 mA for signalling circuit

- Minimum Switching Voltage : 17 V for signalling circuit, 17 V for signalling circuit

- Rated Breaking Capacity : 110 A at 220...230 V conforming to IEC 60947, 110 A at 220...230 V conforming to IEC 60947, 110 A at 220...230 V conforming to IEC 60947, 110 A at 380...400 V conforming to IEC 60947, 110 A at 380...400 V conforming to IEC 60947, 110 A at 380...400 V conforming to IEC 60947, 110 A at 415 V conforming to IEC 60947, 110 A at 415 V conforming to IEC 60947, 110 A at 415 V conforming to IEC 60947, 110 A at 440 V conforming to IEC 60947, 110 A at 440 V conforming to IEC 60947, 110 A at 440 V conforming to IEC 60947, 80 A at 500 V conforming to IEC 60947, 80 A at 500 V conforming to IEC 60947, 80 A at 500 V conforming to IEC 60947, 70 A at 660...690 V conforming to IEC 60947, 70 A at 660...690 V conforming to IEC 60947, 70 A at 660...690 V conforming to IEC 60947

- ICW Rated Short Time Withstand Current : 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 80 A - 1 s for signalling circuit, 80 A - 1 s for signalling circuit, 80 A - 1 s for signalling circuit, 90 A - 500 ms for signalling circuit, 90 A - 500 ms for signalling circuit, 90 A - 500 ms for signalling circuit, 110 A - 100 ms for signalling circuit, 110 A - 100 ms for signalling circuit, 110 A - 100 ms for signalling circuit

- IE Rated Operational Current : 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit

- UC Control Circuit Voltage : 24 V DC, 24 V DC

- UE Rated Operational Voltage : power circuit <= 690 V AC <= 400 Hz, power circuit <= 690 V AC <= 400 Hz, power circuit <= 690 V AC <= 400 Hz, power circuit <= 690 V AC <= 400 Hz, signalling circuit <= 690 V AC <= 400 Hz, signalling circuit <= 690 V AC <= 400 Hz, signalling circuit <= 690 V AC <= 400 Hz, signalling circuit <= 690 V AC <= 400 Hz

- UI Rated Insulation Voltage : power circuit 600 V UL 508, power circuit 600 V UL 508, power circuit 600 V UL 508, power circuit 690 V IEC 60947-4-1, power circuit 690 V IEC 60947-4-1, power circuit 690 V IEC 60947-4-1, signalling circuit 690 V IEC 60947-4-1, signalling circuit 690 V IEC 60947-4-1, signalling circuit 690 V IEC 60947-4-1, signalling circuit 690 V IEC 60947-5-1, signalling circuit 690 V IEC 60947-5-1, signalling circuit 690 V IEC 60947-5-1, signalling circuit 600 V UL 508, signalling circuit 600 V UL 508, signalling circuit 600 V UL 508, power circuit 600 V CSA C22.2 No 14, power circuit 600 V CSA C22.2 No 14, power circuit 600 V CSA C22.2 No 14, signalling circuit 600 V CSA C22.2 No 14, signalling circuit 600 V CSA C22.2 No 14, signalling circuit 600 V CSA C22.2 No 14

- Maximum Motor Phase Current : 6 A

- Maximum Operating Rate : 3600 cyc/h

- UIMP Rated Impulse Withstand Voltage : 8 kV

- Environment Attributes Additional

- Energy Model Manufacturing A1 A3 : Electricity Mix; Low voltage; 2020; France, FR

- Energy Model Installation A5 : No energy used

- Energy Model Use B6 : Electricity Mix; Low voltage; 2020; Europe, EU-27

- Energy Model End Of Life C1 C4 : Global, European and French datasets are used.

- Acidification Ap Mole Of H Equiv Total Life Cycle : 0.5837764456239805

- Acidification Ap Mole Of H Equiv Manufacturing A1 A3 : 0.010969242328260563

- Acidification Ap Mole Of H Equiv Distribution A4 : 0.0005548346657027558

- Acidification Ap Mole Of H Equiv Installation A5 : 0.00003947922543111687

- Acidification Ap Mole Of H Equiv Maintenance B2 : 0

- Acidification Ap Mole Of H Equiv Repair B3 : 0

- Acidification Ap Mole Of H Equiv Replacement B4 : 0

- Acidification Ap Mole Of H Equiv Operational Energy Use B6 : 0.5710475106344288

- Acidification Ap Mole Of H Equiv End Of Life C1 C4 : 0.001165378770157157

- Acidification Ap Mole Of H Equiv Benefits Loads Beyond System Boundaries D : -0.0069554695314433855

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Total Life Cycle : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Manufacturing A1 A3 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Distribution A4 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Installation A5 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Maintenance B2 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Repair B3 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Replacement B4 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C Operational Energy Use B6 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C End Of Life C1 C4 : 0

- Biogenic Carbon Content Of The Associated Packaging Kg Of C BLB SysBound D : 0

- Biogenic Carbon Content Of The Product Kg Of C Total Life Cycle : 0

- Biogenic Carbon Content Of The Product Kg Of C Manufacturing A1 A3 : 0

- Biogenic Carbon Content Of The Product Kg Of C Distribution A4 : 0

- Biogenic Carbon Content Of The Product Kg Of C Installation A5 : 0

- Biogenic Carbon Content Of The Product Kg Of C Maintenance B2 : 0

- Biogenic Carbon Content Of The Product Kg Of C Repair B3 : 0

- Biogenic Carbon Content Of The Product Kg Of C Replacement B4 : 0

- Biogenic Carbon Content Of The Product Kg Of C Operational Energy Use B6 : 0

- Biogenic Carbon Content Of The Product Kg Of C End Of Life C1 C4 : 0

- Biogenic Carbon Content Of The Product Kg Of C Benefits Loads Beyond System Boundaries D : 0

- Climate Change Biogenics Kg Co2 Eq Total Life Cycle : 2.3932206372130804

- Climate Change Biogenics Kg Co2 Eq Manufacturing A1 A3 : -0.020806582681790323

- Climate Change Biogenics Kg Co2 Eq Installation A5 : 0.0006399580567078061

- Climate Change Biogenics Kg Co2 Eq Operational Energy Use B6 : 2.409685011029505

- Climate Change Biogenics Kg Co2 Eq End Of Life C1 C4 : 0.0037022508086579165

- Climate Change Biogenics Kg Co2 Eq Benefits Loads Beyond System Boundaries D : 0.008564143490957741

- Climate Change Fossil Fuels Kg Co2 Eq Total Life Cycle : 108.39059456772311

- Climate Change Fossil Fuels Kg Co2 Eq Manufacturing A1 A3 : 1.2399749542014444

- Climate Change Fossil Fuels Kg Co2 Eq Distribution A4 : 0.08748530601806714

- Climate Change Fossil Fuels Kg Co2 Eq Installation A5 : 0.0128329074012935

- Climate Change Fossil Fuels Kg Co2 Eq Operational Energy Use B6 : 106.68162209337396

- Climate Change Fossil Fuels Kg Co2 Eq End Of Life C1 C4 : 0.36867930672834714

- Climate Change Fossil Fuels Kg Co2 Eq Benefits Loads Beyond System Boundaries D : -0.5621916616104202

- Climate Change Total Kg Co2 Eq Total Life Cycle : 110.7838152753489

- Climate Change Total Kg Co2 Eq Manufacturing A1 A3 : 1.2191683759210354

- Climate Change Total Kg Co2 Eq Distribution A4 : 0.08748530601806714

- Climate Change Total Kg Co2 Eq Installation A5 : 0.013472865458001313

- Climate Change Total Kg Co2 Eq Operational Energy Use B6 : 109.09130710440348

- Climate Change Total Kg Co2 Eq End Of Life C1 C4 : 0.37238162354829996

- Climate Change Total Kg Co2 Eq Benefits Loads Beyond System Boundaries D : -0.5536275181194625

- Components For Re Use Kg Total Life Cycle : 0

- Components For Re Use Kg Manufacturing A1 A3 : 0

- Components For Re Use Kg Distribution A4 : 0

- Components For Re Use Kg Installation A5 : 0

- Components For Re Use Kg Maintenance B2 : 0

- Components For Re Use Kg Repair B3 : 0

- Components For Re Use Kg Replacement B4 : 0

- Components For Re Use Kg Operational Energy Use B6 : 0

- Components For Re Use Kg End Of Life C1 C4 : 0

- Components For Re Use Kg Benefits Loads Beyond System Boundaries D : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Total Life Cycle : 0.0006964359811772087

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Manufacturing A1 A3 : 0.000661045557971028

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Distribution A4 : 0.00000000344889107401

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Installation A5 : 0.00000000033146694096

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Maintenance B2 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Repair B3 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Replacement B4 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Operational Energy Use B6 : 0.00003537071814178658

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb End Of Life C1 C4 : 0.0000000159247063793

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb BLB SysBound D : -0.00015691209917342928

- Depletion Of Abiotic Resources Fossil Fuels Mj Total Life Cycle : 2644.801431441382

- Depletion Of Abiotic Resources Fossil Fuels Mj Manufacturing A1 A3 : 24.05856600278199

- Depletion Of Abiotic Resources Fossil Fuels Mj Distribution A4 : 1.222151843210271

- Depletion Of Abiotic Resources Fossil Fuels Mj Installation A5 : 0.13363999224447037

- Depletion Of Abiotic Resources Fossil Fuels Mj Maintenance B2 : 0

- Depletion Of Abiotic Resources Fossil Fuels Mj Repair B3 : 0

- Depletion Of Abiotic Resources Fossil Fuels Mj Replacement B4 : 0

- Depletion Of Abiotic Resources Fossil Fuels Mj Operational Energy Use B6 : 2616.265496799864

- Depletion Of Abiotic Resources Fossil Fuels Mj End Of Life C1 C4 : 3.1215768032810414

- Depletion Of Abiotic Resources Fossil Fuels Mj Benefits Loads Beyond System Boundaries D : -11.509295395423864

- Ecotoxicity Fresh Water Ctue Total Life Cycle : 850.8005722089321

- Ecotoxicity Fresh Water Ctue Manufacturing A1 A3 : 685.509486921928

- Ecotoxicity Fresh Water Ctue Distribution A4 : 0.057385170085960724

- Ecotoxicity Fresh Water Ctue Installation A5 : 0.18264350818784603

- Ecotoxicity Fresh Water Ctue Maintenance B2 : 0

- Ecotoxicity Fresh Water Ctue Repair B3 : 0

- Ecotoxicity Fresh Water Ctue Replacement B4 : 0

- Ecotoxicity Fresh Water Ctue Operational Energy Use B6 : 163.54489716192532

- Ecotoxicity Fresh Water Ctue End Of Life C1 C4 : 1.5061594468049344

- Ecotoxicity Fresh Water Ctue Benefits Loads Beyond System Boundaries D : -2.8679649781154417

- Emission Of Fine Particles Incidence Of Diseases Total Life Cycle : 0.00000477774279295064

- Emission Of Fine Particles Incidence Of Diseases Manufacturing A1 A3 : 0.00000029429023206465

- Emission Of Fine Particles Incidence Of Diseases Distribution A4 : 0.00000000451206205992

- Emission Of Fine Particles Incidence Of Diseases Installation A5 : 0.00000000023710923415

- Emission Of Fine Particles Incidence Of Diseases Maintenance B2 : 0

- Emission Of Fine Particles Incidence Of Diseases Repair B3 : 0

- Emission Of Fine Particles Incidence Of Diseases Replacement B4 : 0

- Emission Of Fine Particles Incidence Of Diseases Operational Energy Use B6 : 0.00000447081166297574

- Emission Of Fine Particles Incidence Of Diseases End Of Life C1 C4 : 0.00000000789172661618

- Emission Of Fine Particles Incidence Of Diseases BLB SysBound D : -0.00000023570345263592

- Exported Energy Mj By Energy Vector Total Life Cycle : 0.001883006298664303

- Exported Energy Mj By Energy Vector Manufacturing A1 A3 : 0.00003055861596266798

- Exported Energy Mj By Energy Vector Distribution A4 : 0

- Exported Energy Mj By Energy Vector Installation A5 : 0.0005510598254822048

- Exported Energy Mj By Energy Vector Maintenance B2 : 0

- Exported Energy Mj By Energy Vector Repair B3 : 0

- Exported Energy Mj By Energy Vector Replacement B4 : 0

- Exported Energy Mj By Energy Vector Operational Energy Use B6 : 0

- Exported Energy Mj By Energy Vector End Of Life C1 C4 : 0.0013013878572194302

- Exported Energy Mj By Energy Vector Benefits Loads Beyond System Boundaries D : 0

- Freshwater Eutrophication Kg P Eq Total Life Cycle : 0.0002745024780347693

- Freshwater Eutrophication Kg P Eq Manufacturing A1 A3 : 0.00001231245063461186

- Freshwater Eutrophication Kg P Eq Distribution A4 : 0.00000003286187049144

- Freshwater Eutrophication Kg P Eq Installation A5 : 0.00000030905414869505

- Freshwater Eutrophication Kg P Eq Maintenance B2 : 0

- Freshwater Eutrophication Kg P Eq Repair B3 : 0

- Freshwater Eutrophication Kg P Eq Replacement B4 : 0

- Freshwater Eutrophication Kg P Eq Operational Energy Use B6 : 0.0002612887547311676

- Freshwater Eutrophication Kg P Eq End Of Life C1 C4 : 0.0000005593566498034

- Freshwater Eutrophication Kg P Eq Benefits Loads Beyond System Boundaries D : -0.0000013590002687172

- Hazardous Waste Disposed Of Kg Total Life Cycle : 14.388583192334446

- Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 14.386430589245537

- Hazardous Waste Disposed Of Kg Distribution A4 : 0

- Hazardous Waste Disposed Of Kg Installation A5 : 0.000336311341457901

- Hazardous Waste Disposed Of Kg Maintenance B2 : 0

- Hazardous Waste Disposed Of Kg Repair B3 : 0

- Hazardous Waste Disposed Of Kg Replacement B4 : 0

- Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 0

- Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.00181629174745066

- Hazardous Waste Disposed Of Kg Benefits Loads Beyond System Boundaries D : -12.317856165779098

- Human Toxicity Carcinogenic Effects Ctuh Total Life Cycle : 0.00000160848271885529

- Human Toxicity Carcinogenic Effects Ctuh Manufacturing A1 A3 : 0.00000159344220425148

- Human Toxicity Carcinogenic Effects Ctuh Distribution A4 : 0.00000000000153953978

- Human Toxicity Carcinogenic Effects Ctuh Installation A5 : 0.0000000015245849441

- Human Toxicity Carcinogenic Effects Ctuh Maintenance B2 : 0

- Human Toxicity Carcinogenic Effects Ctuh Repair B3 : 0

- Human Toxicity Carcinogenic Effects Ctuh Replacement B4 : 0

- Human Toxicity Carcinogenic Effects Ctuh Operational Energy Use B6 : 0.00000001349302151202

- Human Toxicity Carcinogenic Effects Ctuh End Of Life C1 C4 : 0.00000000002136860792

- Human Toxicity Carcinogenic Effects Ctuh Benefits Loads Beyond System Boundaries D : -0.00000135582127832697

- Human Toxicity Non Carcinogenic Effects Ctuh Total Life Cycle : 0.00000043603704432936

- Human Toxicity Non Carcinogenic Effects Ctuh Manufacturing A1 A3 : 0.00000011502032639201

- Human Toxicity Non Carcinogenic Effects Ctuh Distribution A4 : 0.00000000002978321282

- Human Toxicity Non Carcinogenic Effects Ctuh Installation A5 : 0.00000000003976626416

- Human Toxicity Non Carcinogenic Effects Ctuh Maintenance B2 : 0

- Human Toxicity Non Carcinogenic Effects Ctuh Repair B3 : 0

- Human Toxicity Non Carcinogenic Effects Ctuh Replacement B4 : 0

- Human Toxicity Non Carcinogenic Effects Ctuh Operational Energy Use B6 : 0.00000031960242310857

- Human Toxicity Non Carcinogenic Effects Ctuh End Of Life C1 C4 : 0.0000000013447453518

- Human Toxicity Non Carcinogenic Effects Ctuh Benefits Loads Beyond System Boundaries D : -0.00000007142425287294

- Impacts Related To Land Use Soil Quality Total Life Cycle : 2.8962142952772902

- Impacts Related To Land Use Soil Quality Manufacturing A1 A3 : 0.0008729915237938564

- Impacts Related To Land Use Soil Quality Distribution A4 : 0

- Impacts Related To Land Use Soil Quality Installation A5 : 0.00003687688115501575

- Impacts Related To Land Use Soil Quality Maintenance B2 : 0

- Impacts Related To Land Use Soil Quality Repair B3 : 0

- Impacts Related To Land Use Soil Quality Replacement B4 : 0

- Impacts Related To Land Use Soil Quality Operational Energy Use B6 : 2.8926940145036184

- Impacts Related To Land Use Soil Quality End Of Life C1 C4 : 0.0026104123687230108

- Impacts Related To Land Use Soil Quality Benefits Loads Beyond System Boundaries D : 0

- Ionizing Radiation Human Health Kbq Of U235 Equiv Total Life Cycle : 143.05556184283276

- Ionizing Radiation Human Health Kbq Of U235 Equiv Manufacturing A1 A3 : 0.283915870411273

- Ionizing Radiation Human Health Kbq Of U235 Equiv Distribution A4 : 0.00021338376224269956

- Ionizing Radiation Human Health Kbq Of U235 Equiv Installation A5 : 0.0020610947151803527

- Ionizing Radiation Human Health Kbq Of U235 Equiv Maintenance B2 : 0

- Ionizing Radiation Human Health Kbq Of U235 Equiv Repair B3 : 0

- Ionizing Radiation Human Health Kbq Of U235 Equiv Replacement B4 : 0

- Ionizing Radiation Human Health Kbq Of U235 Equiv Operational Energy Use B6 : 142.7289792196675

- Ionizing Radiation Human Health Kbq Of U235 Equiv End Of Life C1 C4 : 0.04039227427655239

- Ionizing Radiation Human Health Kbq Of U235 Equiv BLB SysBound D : -0.1909765741107065

- Marine Aquatic Eutrophication Kg Of N Equiv Total Life Cycle : 0.06825439510323059

- Marine Aquatic Eutrophication Kg Of N Equiv Manufacturing A1 A3 : 0.0009239226623564845

- Marine Aquatic Eutrophication Kg Of N Equiv Distribution A4 : 0.0002600660887470573

- Marine Aquatic Eutrophication Kg Of N Equiv Installation A5 : 0.00001717095896126759

- Marine Aquatic Eutrophication Kg Of N Equiv Maintenance B2 : 0

- Marine Aquatic Eutrophication Kg Of N Equiv Repair B3 : 0

- Marine Aquatic Eutrophication Kg Of N Equiv Replacement B4 : 0

- Marine Aquatic Eutrophication Kg Of N Equiv Operational Energy Use B6 : 0.0668167179081194

- Marine Aquatic Eutrophication Kg Of N Equiv End Of Life C1 C4 : 0.00023651748504637974

- Marine Aquatic Eutrophication Kg Of N Equiv Benefits Loads Beyond System Boundaries D : -0.0003667849748748047

- Materials For Energy Recovery Kg Total Life Cycle : 0

- Materials For Energy Recovery Kg Manufacturing A1 A3 : 0

- Materials For Energy Recovery Kg Distribution A4 : 0

- Materials For Energy Recovery Kg Installation A5 : 0

- Materials For Energy Recovery Kg Maintenance B2 : 0

- Materials For Energy Recovery Kg Repair B3 : 0

- Materials For Energy Recovery Kg Replacement B4 : 0

- Materials For Energy Recovery Kg Operational Energy Use B6 : 0

- Materials For Energy Recovery Kg End Of Life C1 C4 : 0

- Materials For Energy Recovery Kg Benefits Loads Beyond System Boundaries D : 0

- Materials For Recycling Kg Total Life Cycle : 0.13616954954223398

- Materials For Recycling Kg Manufacturing A1 A3 : 0.0027000077812749518

- Materials For Recycling Kg Distribution A4 : 0

- Materials For Recycling Kg Installation A5 : 0

- Materials For Recycling Kg Maintenance B2 : 0

- Materials For Recycling Kg Repair B3 : 0

- Materials For Recycling Kg Replacement B4 : 0

- Materials For Recycling Kg Operational Energy Use B6 : 0

- Materials For Recycling Kg End Of Life C1 C4 : 0.13346954176095904

- Materials For Recycling Kg Benefits Loads Beyond System Boundaries D : 0

- Net Use Of Fresh Water M3 Total Life Cycle : 0.20697659830960927

- Net Use Of Fresh Water M3 Manufacturing A1 A3 : 0.012321508420207634

- Net Use Of Fresh Water M3 Distribution A4 : 0.00000774599379943032

- Net Use Of Fresh Water M3 Installation A5 : 0.00002425113455253167

- Net Use Of Fresh Water M3 Maintenance B2 : 0

- Net Use Of Fresh Water M3 Repair B3 : 0

- Net Use Of Fresh Water M3 Replacement B4 : 0

- Net Use Of Fresh Water M3 Operational Energy Use B6 : 0.1932779866756267

- Net Use Of Fresh Water M3 End Of Life C1 C4 : 0.0013451060854229515

- Net Use Of Fresh Water M3 Benefits Loads Beyond System Boundaries D : -0.008888159257045933

- Non Hazardous Waste Disposed Of Kg Total Life Cycle : 17.48229427889834

- Non Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 0.808519897632949

- Non Hazardous Waste Disposed Of Kg Distribution A4 : 0.003075179717015036

- Non Hazardous Waste Disposed Of Kg Installation A5 : 0.005772167856604405

- Non Hazardous Waste Disposed Of Kg Maintenance B2 : 0

- Non Hazardous Waste Disposed Of Kg Repair B3 : 0

- Non Hazardous Waste Disposed Of Kg Replacement B4 : 0

- Non Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 16.443934265390663

- Non Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.2209927683011072

- Non Hazardous Waste Disposed Of Kg Benefits Loads Beyond System Boundaries D : -0.5249181840716045

- Ozone Depletion Kg Equivalent Cfc 11 Total Life Cycle : 0.00000113053704051372

- Ozone Depletion Kg Equivalent Cfc 11 Manufacturing A1 A3 : 0.00000065548892932998

- Ozone Depletion Kg Equivalent Cfc 11 Distribution A4 : 0.00000000013429647464

- Ozone Depletion Kg Equivalent Cfc 11 Installation A5 : 0.00000000017474485853

- Ozone Depletion Kg Equivalent Cfc 11 Maintenance B2 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Repair B3 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Replacement B4 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Operational Energy Use B6 : 0.00000046729181769168

- Ozone Depletion Kg Equivalent Cfc 11 End Of Life C1 C4 : 0.00000000744725215888

- Ozone Depletion Kg Equivalent Cfc 11 Benefits Loads Beyond System Boundaries D : -0.00000009183491479537

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Total Life Cycle : 0.21694696840974384

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Manufacturing A1 A3 : 0.0036171435498073795

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Distribution A4 : 0.0007196124789239883

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Installation A5 : 0.00002738058436641605

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Maintenance B2 : 0

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Repair B3 : 0

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Replacement B4 : 0

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Operational Energy Use B6 : 0.2118531696126333

- Photochemical Ozone Formation Kg Of Nmvoc Equiv End Of Life C1 C4 : 0.0007296621840127348

- Photochemical Ozone Formation Kg Of Nmvoc Equiv Benefits Loads Beyond System Boundaries D : -0.0016244374077733358

- Radioactive Waste Disposed Of Kg Total Life Cycle : 0.0042749910162767175

- Radioactive Waste Disposed Of Kg Manufacturing A1 A3 : 0.00038644940906103464

- Radioactive Waste Disposed Of Kg Distribution A4 : 0.00000219023657578222

- Radioactive Waste Disposed Of Kg Installation A5 : 0.00000071341594728352

- Radioactive Waste Disposed Of Kg Maintenance B2 : 0

- Radioactive Waste Disposed Of Kg Repair B3 : 0

- Radioactive Waste Disposed Of Kg Replacement B4 : 0

- Radioactive Waste Disposed Of Kg Operational Energy Use B6 : 0.0038752703986570927

- Radioactive Waste Disposed Of Kg End Of Life C1 C4 : 0.00001036755603552472

- Radioactive Waste Disposed Of Kg Benefits Loads Beyond System Boundaries D : -0.0003099275181714415

- Terrestrial Eutrophication Mole Of N Equiv Total Life Cycle : 1.0871684435779048

- Terrestrial Eutrophication Mole Of N Equiv Manufacturing A1 A3 : 0.0099958393063729

- Terrestrial Eutrophication Mole Of N Equiv Distribution A4 : 0.0028530504714220062

- Terrestrial Eutrophication Mole Of N Equiv Installation A5 : 0.00011944704855290112

- Terrestrial Eutrophication Mole Of N Equiv Maintenance B2 : 0

- Terrestrial Eutrophication Mole Of N Equiv Repair B3 : 0

- Terrestrial Eutrophication Mole Of N Equiv Replacement B4 : 0

- Terrestrial Eutrophication Mole Of N Equiv Operational Energy Use B6 : 1.0714869281904849

- Terrestrial Eutrophication Mole Of N Equiv End Of Life C1 C4 : 0.0027131785610722174

- Terrestrial Eutrophication Mole Of N Equiv Benefits Loads Beyond System Boundaries D : -0.0041625528266134495

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj TLC : 1.4943560903914015

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Mfg A1 A3 : 1.4943560903914015

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Dist A4 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Inst A5 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Maint B2 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Repair B3 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Replament B4 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj EoL C1 C4 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj BLB SysBound D : 0

- Total Use Of Primary Energy During The Life Cycle Mj Total Life Cycle : 3258.451654455975

- Total Use Of Primary Energy During The Life Cycle Mj Manufacturing A1 A3 : 24.858569461108715

- Total Use Of Primary Energy During The Life Cycle Mj Distribution A4 : 1.2237827483978447

- Total Use Of Primary Energy During The Life Cycle Mj Installation A5 : 0.15116724295232606

- Total Use Of Primary Energy During The Life Cycle Mj Maintenance B2 : 0

- Total Use Of Primary Energy During The Life Cycle Mj Repair B3 : 0

- Total Use Of Primary Energy During The Life Cycle Mj Replacement B4 : 0

- Total Use Of Primary Energy During The Life Cycle Mj Operational Energy Use B6 : 3228.8981502724614

- Total Use Of Primary Energy During The Life Cycle Mj End Of Life C1 C4 : 3.319984731054818

- Total Use Of PrE During The Life Cycle Mj BLB SysBound D : -11.929769726590964

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj TLC : 613.6502230145928

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Mfg A1 A3 : 0.8000034583267153

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Dist A4 : 0.0016309051875744265

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Inst A5 : 0.01752725070785567

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Maint B2 : 0

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Repair B3 : 0

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Replament B4 : 0

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj OpEnergy B6 : 612.6326534725969

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj EoL C1 C4 : 0.19840792777377725

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj BLB SysBound D : -0.4204743311671028

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 1.4943560903914015

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 1.4943560903914015

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Maintenance B2 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Repair B3 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Replacement B4 : 0

- Use Of NRE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0

- Use Of NRE PrE Resources Used As RawMats Mj BLB SysBound D : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj TLC : 2643.3070753509905

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Mfg A1 A3 : 22.564209912390595

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Dist A4 : 1.222151843210271

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Inst A5 : 0.13363999224447037

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Maint B2 : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Repair B3 : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Replacement B4 : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj OpEnergy B6 : 2616.265496799864

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj EoL C1 C4 : 3.1215768032810414

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj BLB SysBound D : -11.509295395423864

- Use Of Non Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Non Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Non Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Non Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Non Renewable Secondary Fuels Mj Maintenance B2 : 0

- Use Of Non Renewable Secondary Fuels Mj Repair B3 : 0

- Use Of Non Renewable Secondary Fuels Mj Replacement B4 : 0

- Use Of Non Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Non Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Non Renewable Secondary Fuels Mj Benefits Loads Beyond System Boundaries D : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 0.11155757415254237

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.11155757415254237

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Maintenance B2 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Repair B3 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Replacement B4 : 0

- Use Of RE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of RE PrE Resources Used As RawMats Mj BLB SysBound D : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Benefits Loads Beyond System Boundaries D : -0.21696292372881346

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj TLC : 613.5386654404402

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Mfg A1 A3 : 0.688445884174173

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Dist A4 : 0.0016309051875744265

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Inst A5 : 0.01752725070785567

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Maint B2 : 0

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Repair B3 : 0

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Replacement B4 : 0

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj OpEnergy B6 : 612.6326534725969

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj EoL C1 C4 : 0.19840792777377725

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj BLB SysBound D : -0.2035114074382892

- Use Of Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Renewable Secondary Fuels Mj Maintenance B2 : 0

- Use Of Renewable Secondary Fuels Mj Repair B3 : 0

- Use Of Renewable Secondary Fuels Mj Replacement B4 : 0

- Use Of Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Renewable Secondary Fuels Mj Benefits Loads Beyond System Boundaries D : 0

- Use Of Secondary Materials Kg Total Life Cycle : 0.02101706302680784

- Use Of Secondary Materials Kg Manufacturing A1 A3 : 0.02101706302680784

- Use Of Secondary Materials Kg Distribution A4 : 0

- Use Of Secondary Materials Kg Installation A5 : 0

- Use Of Secondary Materials Kg Maintenance B2 : 0

- Use Of Secondary Materials Kg Repair B3 : 0

- Use Of Secondary Materials Kg Replacement B4 : 0

- Use Of Secondary Materials Kg Operational Energy Use B6 : 0

- Use Of Secondary Materials Kg End Of Life C1 C4 : 0

- Use Of Secondary Materials Kg Benefits Loads Beyond System Boundaries D : 0

- Water Use M3 Eq Total Life Cycle : 8.84885765923197

- Water Use M3 Eq Manufacturing A1 A3 : 0.5289939523414813

- Water Use M3 Eq Distribution A4 : 0.0003326904336855324

- Water Use M3 Eq Installation A5 : 0.0010412802569658797

- Water Use M3 Eq Maintenance B2 : 0

- Water Use M3 Eq Repair B3 : 0

- Water Use M3 Eq Replacement B4 : 0

- Water Use M3 Eq Operational Energy Use B6 : 8.269959788864144

- Water Use M3 Eq End Of Life C1 C4 : 0.048529947335692256

- Water Use M3 Eq Benefits Loads Beyond System Boundaries D : -0.381729948632481

- Air Pollution M3 Total Life Cycle : 0

- Air Pollution M3 Manufacturing A1 A3 : 0

- Air Pollution M3 Distribution A4 : 0

- Air Pollution M3 Installation A5 : 0

- Air Pollution M3 Maintenance B2 : 0

- Air Pollution M3 Repair B3 : 0

- Air Pollution M3 Replacement B4 : 0

- Air Pollution M3 Operational Energy Use B6 : 0

- Air Pollution M3 End Of Life C1 C4 : 0

- Air Pollution M3 Benefits Loads Beyond System Boundaries D : 0

- Water Pollution M3 Total Life Cycle : 0

- Water Pollution M3 Manufacturing A1 A3 : 0

- Water Pollution M3 Distribution A4 : 0

- Water Pollution M3 Installation A5 : 0

- Water Pollution M3 Maintenance B2 : 0

- Water Pollution M3 Repair B3 : 0

- Water Pollution M3 Replacement B4 : 0

- Water Pollution M3 Operational Energy Use B6 : 0

- Water Pollution M3 End Of Life C1 C4 : 0

- Water Pollution M3 Benefits Loads Beyond System Boundaries D : 0

- Important Information Attributes

- Persona Type Ids : EU, LC, OM, OM8, PB, SI

- Persona Type Names : End User, Contractor, Original Equipment Manufacturer, OEM - Control Panelbuilder, Panel Builder, System Integrator

- Market Segmentation Id : COMMERCIAL, INDUSTRIAL

- Market Segmentation : Commercial, Industrial

- Associated Fuse Rating : 25 A gG at <= 440 V for power circuit, 25 A gG at <= 440 V for power circuit, 25 A gG at <= 440 V for power circuit, 25 A gG at <= 440 V for power circuit, 25 A aM for power circuit, 25 A aM for power circuit, 25 A aM for power circuit, 10 A gG for signalling circuit conforming to IEC 60947, 10 A gG for signalling circuit conforming to IEC 60947, 10 A gG for signalling circuit conforming to IEC 60947, 10 A gG for signalling circuit conforming to IEC 60947, 10 A gG for signalling circuit conforming to VDE 0660, 10 A gG for signalling circuit conforming to VDE 0660, 10 A gG for signalling circuit conforming to VDE 0660, 10 A gG for signalling circuit conforming to VDE 0660

- Average Impedance : 3 mOhm - Ith 20 A 50 Hz for power circuit, 3 mOhm - Ith 20 A 50 Hz for power circuit, 3 mOhm - Ith 20 A 50 Hz for power circuit, 3 mOhm - Ith 20 A 50 Hz for power circuit

- Electrical Durability : 1.3 Mcycles 6 A AC-3 <= 440 V, 1.3 Mcycles 6 A AC-3 <= 440 V, 1.3 Mcycles 6 A AC-3 <= 440 V, 1.3 Mcycles 6 A AC-3 <= 440 V, 1.3 Mcycles 6 A AC-3e <= 440 V, 1.3 Mcycles 6 A AC-3e <= 440 V, 1.3 Mcycles 6 A AC-3e <= 440 V, 1.3 Mcycles 6 A AC-3e <= 440 V, 0.05 Mcycles 36 A AC-4 <= 440 V, 0.05 Mcycles 36 A AC-4 <= 440 V, 0.05 Mcycles 36 A AC-4 <= 440 V, 0.05 Mcycles 36 A AC-4 <= 440 V

- Flame Retardance : V1 conforming to UL 94, V1 conforming to UL 94, requirement 2 conforming to NF F 16-101, requirement 2 conforming to NF F 16-101, requirement 2 conforming to NF F 16-102, requirement 2 conforming to NF F 16-102

- Hold In Power Consumption In W : 3-3 W 20 °C, 3-3 W 20 °C

- Inrush Power In W : 3-3 W 20 °C), 3-3 W 20 °C)

- Insulation Resistance : > 10 MOhm for signalling circuit, > 10 MOhm for signalling circuit

- Motor Power KW : 1.5 kW 220...230 V AC 50/60 Hz AC-3, 1.5 kW 220...230 V AC 50/60 Hz AC-3, 1.5 kW 220...230 V AC 50/60 Hz AC-3, 1.5 kW 220...230 V AC 50/60 Hz AC-3, 1.5 kW 220...230 V AC 50/60 Hz AC-3, 2.2 kW 380...415 V AC 50/60 Hz AC-3, 2.2 kW 380...415 V AC 50/60 Hz AC-3, 2.2 kW 380...415 V AC 50/60 Hz AC-3, 2.2 kW 380...415 V AC 50/60 Hz AC-3, 2.2 kW 380...415 V AC 50/60 Hz AC-3, 3 kW 440/690 V AC 50/60 Hz AC-3, 3 kW 440/690 V AC 50/60 Hz AC-3, 3 kW 440/690 V AC 50/60 Hz AC-3, 3 kW 440/690 V AC 50/60 Hz AC-3, 3 kW 440/690 V AC 50/60 Hz AC-3, 1.5 kW 220...230 V AC 50/60 Hz AC-3e, 1.5 kW 220...230 V AC 50/60 Hz AC-3e, 1.5 kW 220...230 V AC 50/60 Hz AC-3e, 1.5 kW 220...230 V AC 50/60 Hz AC-3e, 1.5 kW 220...230 V AC 50/60 Hz AC-3e, 2.2 kW 380...415 V AC 50/60 Hz AC-3e, 2.2 kW 380...415 V AC 50/60 Hz AC-3e, 2.2 kW 380...415 V AC 50/60 Hz AC-3e, 2.2 kW 380...415 V AC 50/60 Hz AC-3e, 2.2 kW 380...415 V AC 50/60 Hz AC-3e, 3 kW 440/690 V AC 50/60 Hz AC-3e, 3 kW 440/690 V AC 50/60 Hz AC-3e, 3 kW 440/690 V AC 50/60 Hz AC-3e, 3 kW 440/690 V AC 50/60 Hz AC-3e, 3 kW 440/690 V AC 50/60 Hz AC-3e, 1.5 kW 220...230 V AC 50/60 Hz AC-4, 1.5 kW 220...230 V AC 50/60 Hz AC-4, 1.5 kW 220...230 V AC 50/60 Hz AC-4, 1.5 kW 220...230 V AC 50/60 Hz AC-4, 1.5 kW 220...230 V AC 50/60 Hz AC-4, 2.2 kW 380...415 V AC 50/60 Hz AC-4, 2.2 kW 380...415 V AC 50/60 Hz AC-4, 2.2 kW 380...415 V AC 50/60 Hz AC-4, 2.2 kW 380...415 V AC 50/60 Hz AC-4, 2.2 kW 380...415 V AC 50/60 Hz AC-4, 3 kW 440/690 V AC 50/60 Hz AC-4, 3 kW 440/690 V AC 50/60 Hz AC-4, 3 kW 440/690 V AC 50/60 Hz AC-4, 3 kW 440/690 V AC 50/60 Hz AC-4, 3 kW 440/690 V AC 50/60 Hz AC-4

- Operating Time : 30...40 ms coil energisation and NO closing, 30...40 ms coil energisation and NO closing, 10 ms coil de-energisation and NO opening, 10 ms coil de-energisation and NO opening

- Safety Reliability Level : B10d = 1369863 cycles contactor with nominal load EN/ISO 13849-1, B10d = 1369863 cycles contactor with nominal load EN/ISO 13849-1, B10d = 1369863 cycles contactor with nominal load EN/ISO 13849-1, B10d = 1369863 cycles contactor with nominal load EN/ISO 13849-1, B10d = 20000000 cycles contactor with mechanical load EN/ISO 13849-1, B10d = 20000000 cycles contactor with mechanical load EN/ISO 13849-1, B10d = 20000000 cycles contactor with mechanical load EN/ISO 13849-1, B10d = 20000000 cycles contactor with mechanical load EN/ISO 13849-1

- Tightening Torque : 0.8-1.3 N.m screw clamp terminals Philips No 2, 0.8-1.3 N.m screw clamp terminals Philips No 2, 0.8-1.3 N.m screw clamp terminals Philips No 2, 0.8-1.3 N.m screw clamp terminals flat Ø 6 mm, 0.8-1.3 N.m screw clamp terminals flat Ø 6 mm, 0.8-1.3 N.m screw clamp terminals flat Ø 6 mm

- ICW Rated Short Time Withstand Current : 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 90 A 50 °C - 1 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 85 A 50 °C - 5 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 80 A 50 °C - 10 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 60 A 50 °C - 30 s for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 45 A 50 °C - 1 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 40 A 50 °C - 3 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 20 A 50 °C - >= 15 min for power circuit, 80 A - 1 s for signalling circuit, 80 A - 1 s for signalling circuit, 80 A - 1 s for signalling circuit, 90 A - 500 ms for signalling circuit, 90 A - 500 ms for signalling circuit, 90 A - 500 ms for signalling circuit, 110 A - 100 ms for signalling circuit, 110 A - 100 ms for signalling circuit, 110 A - 100 ms for signalling circuit

- IE Rated Operational Current : 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3 for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit, 6 A (at <60 °C) at <= 440 V AC AC-3e for power circuit

- ITH Conventional Free Air Thermal Current : 20 A (at 60 °C) for power circuit, 20 A (at 60 °C) for power circuit, 20 A (at 60 °C) for power circuit, 10 A (at 50 °C) for signalling circuit, 10 A (at 50 °C) for signalling circuit, 10 A (at 50 °C) for signalling circuit

- Connections Terminals : screw clamp terminals 1 1.5-4 mm²solid, screw clamp terminals 1 1.5-4 mm²solid, screw clamp terminals 1 1.5-4 mm²solid, screw clamp terminals 1 1.5-4 mm²solid, screw clamp terminals 1 0.75-4 mm²flexible without cable end, screw clamp terminals 1 0.75-4 mm²flexible without cable end, screw clamp terminals 1 0.75-4 mm²flexible without cable end, screw clamp terminals 1 0.75-4 mm²flexible without cable end, screw clamp terminals 1 0.75-4 mm²flexible without cable end, screw clamp terminals 1 0.34-2.5 mm²flexible with cable end, screw clamp terminals 1 0.34-2.5 mm²flexible with cable end, screw clamp terminals 1 0.34-2.5 mm²flexible with cable end, screw clamp terminals 1 0.34-2.5 mm²flexible with cable end, screw clamp terminals 1 0.34-2.5 mm²flexible with cable end, screw clamp terminals 2 1.5-4 mm²solid, screw clamp terminals 2 1.5-4 mm²solid, screw clamp terminals 2 1.5-4 mm²solid, screw clamp terminals 2 1.5-4 mm²solid, screw clamp terminals 2 0.75-4 mm²flexible without cable end, screw clamp terminals 2 0.75-4 mm²flexible without cable end, screw clamp terminals 2 0.75-4 mm²flexible without cable end, screw clamp terminals 2 0.75-4 mm²flexible without cable end, screw clamp terminals 2 0.75-4 mm²flexible without cable end, screw clamp terminals 2 0.34-1.5 mm²flexible with cable end, screw clamp terminals 2 0.34-1.5 mm²flexible with cable end, screw clamp terminals 2 0.34-1.5 mm²flexible with cable end, screw clamp terminals 2 0.34-1.5 mm²flexible with cable end, screw clamp terminals 2 0.34-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end, power circuit screw clamp terminals 2 1.5-1.5 mm²flexible with cable end

- Add Ons : LA1KN22, LA1KN11, LA1KN40, LA1KN31, LA1KN20, LA1KN04, LA1KN02, LA1KN13

- Auxiliaries : LA4KE1B, LA4KC1B

- Local Data Status : Publishable

- Local Publishable Date : 2025-02-26

- HTML Description : TeSys K ContactorNumber of Poles: 3-PolesPole Contact Composition: 3 NORated Operational Current: 6AControl Circuit Voltage: 24V DCNon-Reversing

- Manufacturer : Schneider Electric

- Device Type : LV equipment - LV contactor

- Serviceability : No

- Traceability : No

- Field Service Division : PPIBS

- Average Life Duration : 20 year(s)

- Legacy WEEE Scope : In

- Scope Perimeter : At least in Europe

- EOLI Availability Display : Yes

- End Of Life Doc Ref : ENVEOLI1503003

- Reach Full Compliance Status : Free of Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : NOT_CONTAINING_SVHC

- Reach Compliance Directive : Free of Substances of Very High Concern above the threshold

- ROHS EUR In Scope : Yes

- ROHS EUR Status : Compliant

- ROHS EUR Full Compliance Status : Compliant

- ROHS EUR Full Compliance Status Id : COMPLIANT

- Green Premium Status For Reporting : Green Premium product

- With Recycled Cardboard : Yes

- Without Single Use Plastic : Yes

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : Y

- WD Status : 1 - GSC certified

- Function Option Id : STANDARD

- Function Option : Standard

- Coil Technology : without built-in suppressor module

- Compatibility Code : LP1K

- Contactor Application : motor control

- Device Short Name : LP1K

- Heat Dissipation : 1.3-1.3 W

- Package Weight Lbs : 219.000 g

- Product Availability : Stock - Normally stocked in distribution facility

- Product Or Component Type : contactor

- Range : TeSys

- Range Of Product : TeSys K

- Returnability : Yes

- Sustainable Packaging : Yes

- Total Lifecycle Carbon Footprint : 111 kg CO2 eq.

- Weee Label : The product must be disposed on European Union markets following specific waste collection and never end up in rubbish bins.

- Relationship Type : Compatible relationship

- Pep Code : ENVPEP1503003

- Pep Verification Date : 2025-11-21

- PCR Version : PEP-PCR-ed4-2021 09 06

- PSR Version : PSR-0005-ed3-2023 06 06

- Type Of Verification For The Pep : Independent internal review

- Functional Unit Description : Establish and cut off the supply of a downstream installation from an electrical and/or mechanical control characterised by the composition of the poles or type of contacts X, a rated voltage of Ue, a rated current Ie, a control circuit voltage Uc, with Np poles, and if applicable the specific specifications, in the Household/Commercial or Industrial application areas, according to the appropriate use scenario, and during the reference service life of the product of 20 years

- Functional Unit Unit : unit

- Product Kit Identifier : N

- Huella De Carbono De La Fase De Distribución A4 : 0.1 kg CO2 eq.

- Huella De Carbono De La Fase De Fabricación A1 A A3 : 1 kg CO2 eq.

- Huella De Carbono De La Fase De Fin De Vida C1 A C4 : 0.4 kg CO2 eq.

- Huella De Carbono De La Fase De Instalación A5 : 0 kg CO2 eq.

- Huella De Carbono De La Fase De Uso B2 B3 B4 B6 : 109 kg CO2 eq.

- Environment Attributes Main

- EU ROHS Directive : Compliant, Compliant

- Operating Altitude : 6561.68 ft (2000 m) without derating, 6561.68 ft (2000 m) without derating

- ROHS Exemption Information : Yes

- Take Back : No

- Reach Free SHVC : Yes

- Recycled Metal Content At Cr Level : 0 %

- China ROHS Regulation : X

- Toxic Heavy Metal Free : Yes

- Mercury Free : Yes

- Carbon Footprint : 110.7838152753489

- Ambient Air Temperature For Operation : -25-50 °C

- Circularity Profile : ENVEOLI1503003

- Environmental Disclosure : ENVPEP1503003

- IP Degree Of Protection : IP2X

- Packaging Made With Recycled Cardboard : Yes

- Packaging Without Single Use Plastic : Yes

- Reach Free Of SVHC : Yes

- Reach Regulation : Free of Substances of Very High Concern above the threshold

- Pep Code : ENVPEP1503003

- Pep Verification Date : 2025-11-21

- PCR Version : PEP-PCR-ed4-2021 09 06

- PSR Version : PSR-0005-ed3-2023 06 06

- Type Of Verification For The Pep : Independent internal review

- General Attributes

- Product Or Component Type : contactor

- Range Of Product : TeSys K

- Contractual Warranty Attributes

- Warranty Period : 18 months

- Warranty : 18 months