-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

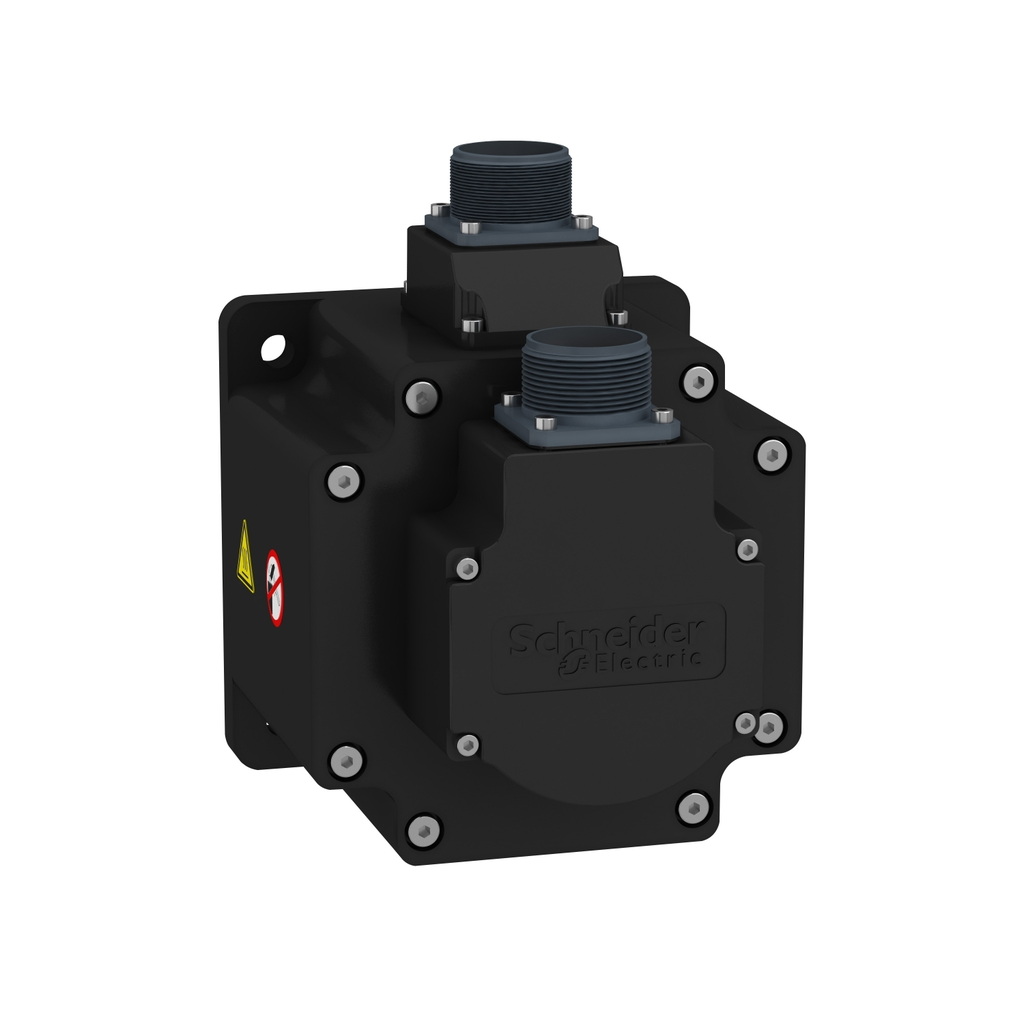

servo motor BCH, Lexium 28, 130mm, 600W, 6.91kg.cm², with oil seal, with key, brake, straight connection

servo motor BCH, Lexium 28, 130mm, 600W, 6.91kg.cm², with oil seal, with key, brake, straight connection

SQDBCH2MM0613CF6C

BCH2MM0613CF6C

3606480734595

2999.98

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-Servo-motor-BCH-130mm-600W-w-oil-seal-w-key-brake-straight-con-785901829263

- Shaft Diameter: 22 mm

- Shaft End: Keyed

- Shaft Length: 45 mm

- ca9d9fcea2fdb5a3ad9a1839759d2289f9d73550files?p_Doc_Ref=NHA3487300(Download)

- 8ddd6aae5975e84bca1ac83ed833f41e32c6830cfiles?p_Doc_Ref=EUDoC_NVE7096800(Download)

- 2c56d0da4a59files?p_Doc_Ref=BCH2_UL_certificate&p_File_name=E468964-Vol1-20250731_UL certificate.pdf(Download)

- 57bb78daabc514b70ec4f9b2a6f57689c7files?p_Doc_Ref=ENVPEP1504002EN&p_File_name=ENVPEP1504002EN_V2.pdf(Download)

- c24170afaa40f677ddf0b378c03ea1d616ed923cBCH2MM0613CF6C(Download)

- 49b377ae90f15283ceed8f860b1ce03afiles?p_Doc_Ref=ENVEOLI1504002EN&p_File_name=ENVEOLI1504002EN_V2.pdf(Download)

- e9ec6fe76f9777files?p_Doc_Ref=BU_AUT_F19_Servo_Motor_EN&p_File_name=BU_AUT_F19_Servo_Motor_EN_V3.zip(Download)

- b49670f0cc9b121caab4689d6b81b2dc017cc8b4files?p_Doc_Ref=MCADID0000116_3D-CAD(Download)

- 56db7627bc93e658d5f0dfa48360833d478738f8files?p_Doc_Ref=DIA7ED2141002EN(Download)

- 5159f15c61171e2a0befd2a5d40ef9995e94a5eefiles?p_Doc_Ref=DIA7ED2150401EN(Download)

- ead6cc153ce73d4f578a924f778af53d2f512a41files?p_Doc_Ref=0198441114054-EN(Download)

- d91838f522ace024bbe87b4f64446e6aa1bd2f66files?p_Doc_Ref=EIO0000002299(Download)

- 8a471a48bb28b0f11fc368aaf1cda885ba332bbbfiles?p_Doc_Ref=EIO0000002305(Download)

- 26506d7debc2f1aaf28b676c3a9162fed3b6ecf2files?p_Doc_Ref=EIO0000002454(Download)

- Features

- Specifications

- Prop 65

- WARNING: This product can expose you to chemicals including: Lead and lead compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Physical Attributes

- Key Width : 8 mm

- Motor Flange Size : 130 mm

- Shaft Length : 45 mm

- Complementary Attributes

- Maximum Current IRMS : 13.44 A LXM28... 0.6 kW, 220 V, 13.44 A LXM28... 0.6 kW, 110 V, 13.5 A

- Maximum Ambient Air Temperature For Operation : 40.0 °C

- Maximum Mechanical Speed : 3000 rpm

- Maximum Operational Altitude : 1000.0 m

- Maximum Radial Force FR : 670 N 1000 rpm

- Minimum Ambient Air Temperature For Operation : 0.0 °C

- Minimum Operational Altitude : 0.0 m

- Maximum In Rated Current : 4.1 A

- Important Information Attributes

- Persona Type Ids : EU, OM, OM8

- Persona Type Names : End User, Original Equipment Manufacturer, OEM - Control Panelbuilder

- Continuous Stall Torque : 5.73 N.m LXM26D 4.5 A, 220 V, single phase, 5.73 N.m LXM26D 4.5 A, 220 V, three phase, 5.73 N.m LXM28 4.5 A, 220 V, single phase, 5.73 N.m LXM28 4.5 A, 220 V, three phase, 5.73 N.m LXM28 9 A, 110 V, single phase

- Inertia : 6.9 kg.cm² of brake, 6.91 kg.cm² of motor

- Nominal Speed : 1000 rpm LXM26D 4.5 A, 220 V, single phase, 1000 rpm LXM26D 4.5 A, 220 V, three phase, 1000 rpm LXM28... 4.5 A, 220 V, single phase, 1000 rpm LXM28... 4.5 A, 220 V, three phase, 1000 rpm LXM28... 9 A, 110 V, single phase

- Nominal Torque : 5.73 N.m half speed, 5.73 N.m full speed, 5.73 N.m LXM26D 4.5 A, 220 V, single phase, 5.73 N.m LXM26D 4.5 A, 220 V, three phase, 5.73 N.m LXM28... 4.5 A, 220 V, single phase, 5.73 N.m LXM28... 4.5 A, 220 V, three phase, 5.73 N.m LXM28... 9 A, 110 V, single phase

- Peak Stall Torque : 17.19 N.m LXM26D 4.5 A, 220 V, single phase, 17.19 N.m LXM26D 4.5 A, 220 V, three phase, 17.19 N.m LXM28... 4.5 A, 220 V, single phase, 17.19 N.m LXM28... 4.5 A, 220 V, three phase, 17.19 N.m LXM28... 9 A, 110 V, single phase

- Carbon Footprint Of The Distribution Phase A4 : 1.207670852, 1 kg CO2 eq.

- Carbon Footprint Of The End Of Life Phase C1 To C4 : 1 kg CO2 eq., 1.0052870852

- Carbon Footprint Of The Installation Phase A5 : 0.0596563587, 0.1 kg CO2 eq.

- Carbon Footprint Of The Manufacturing Phase A1 To A3 : 54 kg CO2 eq., 53.6458116592

- Carbon Footprint Of The Use Phase B2 B3 B4 B6 : 3 275 kg CO2 eq., 3274.7156428171

- Local Data Status : Publishable

- Local Publishable Date : 2026-01-12

- Device Type : Motion - drive & motor

- Serviceability : Yes

- Traceability : Yes

- Field Service Division : IDIBS

- Average Life Duration : 15 year(s)

- Legacy WEEE Scope : Out

- Scope Perimeter : At least in Europe

- EOLI Availability Display : Yes

- End Of Life Doc Ref : ENVEOLI1504002EN

- Reach Full Compliance Status : Free of Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : NOT_CONTAINING_SVHC

- Reach Compliance Directive : Free of Substances of Very High Concern above the threshold

- ROHS EUR In Scope : No

- ROHS EUR Status : Compliant

- ROHS EUR Full Compliance Status : Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS EUR Full Compliance Status Id : PRO_ACTIVE_COMPLIANCE

- China ROHS In Scope : Yes

- Green Premium Status For Reporting : Green Premium product

- With Recycled Cardboard : No

- Without Single Use Plastic : No

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : N

- WD Status : 5 - INITIALIZED WITH DataSCAN OK (Migration)

- Function Option Id : ADVANCED

- Function Option : Advanced

- Market Segmentation Id : INDUSTRIAL

- Market Segmentation : Industrial

- Brake Pull In Power : 19.7 W

- Centring Collar Diameter : 110 mm

- Circle Diameter Of The Mounting Holes : 145 mm

- Coefficient 1 1 : -1.87500000003E-05 N.m/rpm

- Coefficient 1 2 : 5.62440546E-19 N.m/rpm²

- Coefficient 1 3 : -2.965143E-22 N.m/rpm3

- Coefficient 1 4 : 7.11E-26 N.m/rpm4

- Coefficient 1 5 : -7.8919E-30 N.m/rpm5

- Coefficient 1 6 : 3.2E-34 N.m/rpm6

- Coefficient 2 0 : 0 N.m

- Coefficient 2 1 : 8.75000000000026E-06 N.m/rpm

- Continuous Stall Current : 3.77 A

- Derating Altitude Start : 1000.0 m

- Derating Temperature Scale : 40.0 °C

- Derating Temperature Start : 40.0 °C

- Device Short Name : BCH2

- Distance Shaft Shoulder Flange : 8 mm

- Electrical Connection : connector MIL

- Feedback Type : 20 bits single turn absolute encoder

- Holding Brake : with

- Holding Torque : 9.6 N.m built-in

- Maximum Operational Altitude : 1000.0 m

- Minimum Ambient Air Temperature For Operation : 0.0 °C

- Minimum Operational Altitude : 0.0 m

- Motor Figures : 230.0 V

- Mounting Holes Diameter : 9.2 mm

- Package Weight Lbs : 9360 g

- Peak Nominal Torque : 17.19 N.m

- Product Availability : Non-Stock - Not normally stocked in distribution facility

- Product Or Component Type : servo motor

- Returnability : No

- Shaft Diameter : 22 mm

- Shaft End : keyed

- Sizing Reference : BCH2

- Stator Electrical Time Constant : 12.9 ms 20 °C

- Stator Inductance : 23.91 mH 20 °C

- Stator Resistance : 1.93 Ohm 20 °C

- Sustainable Packaging : No

- Temperature Copper Hot : 135 °C

- Temperature Magnet Hot : 100 °C

- Temperature Magnet RT : 20 °C

- Torque Constant : 1.52 N.m/A 20 °C

- Total Lifecycle Carbon Footprint : 3 331 kg CO2 eq.

- Maximum In Rated Current : 4.1 A

- Relationship Type : Compatible relationship

- Pep Code : ENVPEP1504002EN

- Pep Verification Date : 2020-11-01

- PCR Version : PCR-ed3-EN-2015 04 02

- Type Of Verification For The Pep : Independent internal review

- Functional Unit Description : To coordinate and synchronize motion control with a nominal torque from 0.16 Nm to 28.6 Nm and a nominal speed of from 1,500 to 3,000 rpm 70% of the time for 10 years

- Functional Unit Unit : unité (unit)

- Product Kit Identifier : N

- Product Manager : JINGWEN HU

- Environment Attributes Main

- EU ROHS Directive : Compliant, Pro-active compliance (Product out of EU RoHS legal scope)

- IP Degree Of Protection : IP50 IM V3, IP65 IM B5, IM V1

- Product Compatibility : LXM26D servo drive 0.6 kW, 220 V, single phase, LXM26D servo drive 0.6 kW, 220 V, three phase, LXM28... servo drive 0.6 kW, 220 V, single phase, LXM28... servo drive 0.6 kW, 220 V, three phase, LXM28... servo drive 0.6 kW, 110 V, single phase

- ROHS Exemption Information : Yes

- Take Back : No

- Reach Free SHVC : Yes

- Recycled Metal Content At Cr Level : 0 %

- China ROHS Regulation : X

- Toxic Heavy Metal Free : Yes

- Mercury Free : Yes

- Carbon Footprint : 3330.6340687723

- Circularity Profile : ENVEOLI1504002EN

- Environmental Disclosure : ENVPEP1504002EN

- Packaging Made With Recycled Cardboard : No

- Packaging Without Single Use Plastic : No

- Reach Free Of SVHC : Yes

- Reach Regulation : Free of Substances of Very High Concern above the threshold

- Pep Code : ENVPEP1504002EN

- Pep Verification Date : 2020-11-01

- PCR Version : PCR-ed3-EN-2015 04 02

- Type Of Verification For The Pep : Independent internal review

- General Attributes

- Product Or Component Type : servo motor

- Output Attributes

- Nominal Output Power : 600 W LXM26D 4.5 A, 220 V, single phase, 600 W LXM26D 4.5 A, 220 V, three phase, 600 W LXM28... 4.5 A, 220 V, single phase, 600 W LXM28... 4.5 A, 220 V, three phase, 600 W LXM28... 9 A, 110 V, single phase