-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

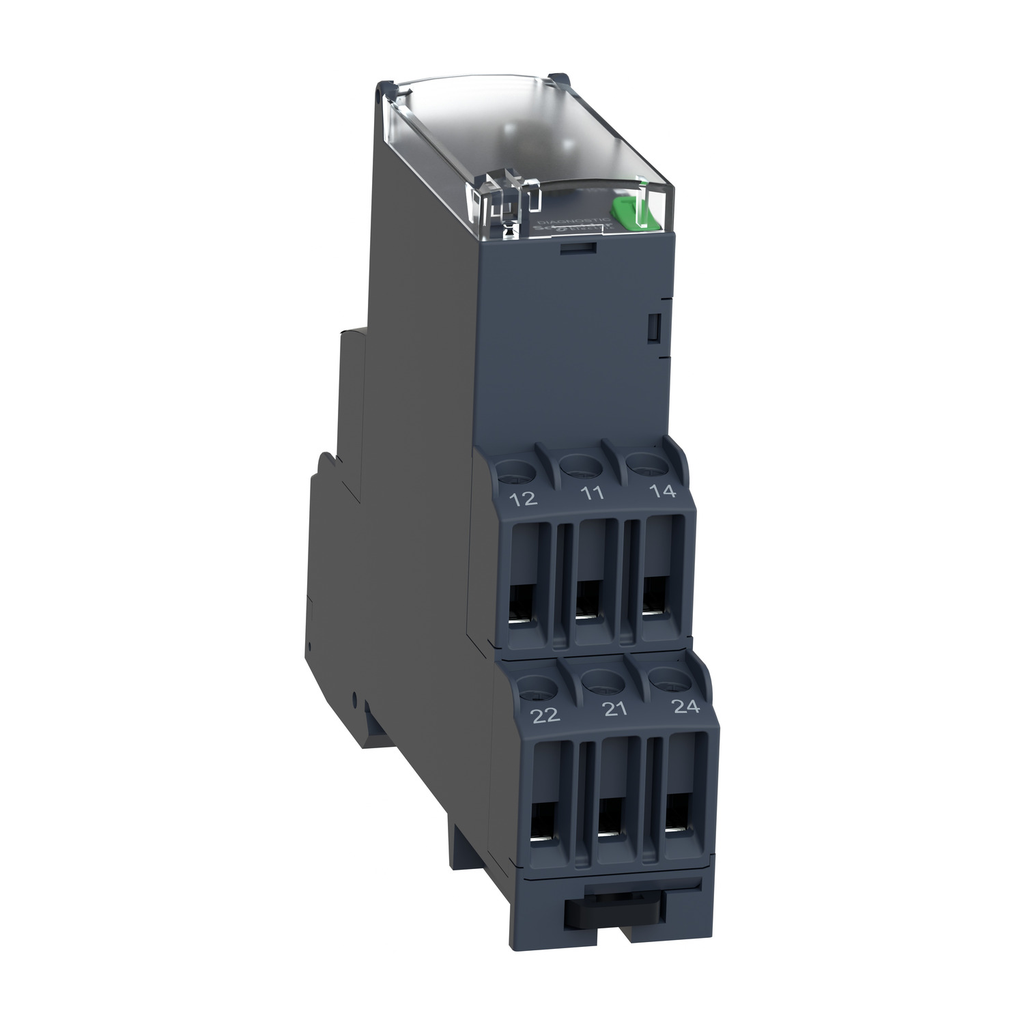

3-phase control relay, Harmony Control Relays, 5A, 2CO, 380...480V AC

3-phase control relay, Harmony Control Relays, 5A, 2CO, 380...480V AC

SQDRM22TA33

RM22TA33

3606480792151

183.05

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-Modular-3-phase-supply-control-relay-5-A-2-CO-208-440-V-AC-785901694311

- Country of Origin: Indonesia

This Harmony RM22TA asymmetry control relay allows monitoring of power supply circuits in 3-phase networks. This modular 3-phase control relay is ideal for monitoring of electrical values in industrial and building control panels. It applies to a wide type of industrial automation applications such as hoisting, packaging, lifts, textile, water. It has one of market slim form-factors with 22.5mm width, allowing for a flexible and easy installation on DIN rail, using the same space as any modular 1-pole DIN device. It also offers a selectable memory function, integral LED for indicating control status, sealable cover, with simple and precise settings with screw trimmers. It provides automatic shutdown management and fault information to user for a quick fault identification and troubleshooting. Multi function controller for wide choice selected in hard-wired logic automated systems, ideal for refurbishment of old installations without using a PLC. 0 0 0 0 0 0 0 0 0 0 0 0

- E6EmoxCSol0?si=pgsC4CGbLrNit1R8IDSIG_PROMO_VIDEO_21_EN(Video)

- 32d542ba233c11026aa20e931733c98cb3b84dedfiles?p_Doc_Ref=CNCA-CCC-RM22-RM35(Download)

- 36e4e50adfef977f0f952fa097fc2b9f21cda43c250321%20248382-2137886%20CofC.pdf(Download)

- 31b4c5c8f65f7bdc8e6ebe69c9f387ea14e7d611250319%20E173076%20CofC.pdf(Download)

- a280956cfacb0de6d172e2d34b79cbcd912cd94afiles?p_Doc_Ref=DNVGL-Certificate-TAA00002DH(Download)

- 25f82238a270a532a766b8744e278249ae6c9files?p_Doc_Ref=ENVPEP2506066EN&p_File_name=ENVPEP2506066EN.pdf(Download)

- fb48377ce1c795760d8f2496b3ea253b436bcc2cRM22TA33(Download)

- b1bfab8ecec3ebf4bc06c47347fcc39ad08files?p_Doc_Ref=ENVEOLI2506066EN&p_File_name=ENVEOLI2506066EN.pdf(Download)

- 7c746054455e93e5aaa1823fb0acef8b2842cd0dfiles?p_Doc_Ref=UK-DOC-02-03-RM22-RM35(Download)

- 4228005c86c5e6468c90fa1d25f1f7abf10feec9files?p_Doc_Ref=EU-DOC-02-03-RM22-RM35(Download)

- 56facb5fb7d65aa312de6aadec2be1bbf782c992files?p_Doc_Ref=Supplier DOC-RM22 RM35(Download)

- 0e70a7ffd3945c2files?p_Doc_Ref=PKR6406600&p_File_name=Harmony 3 Phase Control Relay (Web_250716).pdf(Download)

- 8e0a5fffe4650320files?p_Doc_Ref=eTechPub Zelio Control V4 EN&p_File_name=BU_AUT_528_EPDS_V_04_EN.zip(Download)

- 810b62c93bd8f8c276df3d55dc6b676f0b060files?p_Doc_Ref=DIA5ED2160501EN&p_File_name=DIA5ED2160501EN.pdf(Download)

- Product Description

- Features

- Specifications

This Harmony RM22TA asymmetry control relay allows monitoring of power supply circuits in 3-phase networks. This modular 3-phase control relay is ideal for monitoring of electrical values in industrial and building control panels. It applies to a wide type of industrial automation applications such as hoisting, packaging, lifts, textile, water. It has one of market slim form-factors with 22.5mm width, allowing for a flexible and easy installation on DIN rail, using the same space as any modular 1-pole DIN device. It also offers a selectable memory function, integral LED for indicating control status, sealable cover, with simple and precise settings with screw trimmers. It provides automatic shutdown management and fault information to user for a quick fault identification and troubleshooting. Multi function controller for wide choice selected in hard-wired logic automated systems, ideal for refurbishment of old installations without using a PLC. 0 0 0 0 0 0 0 0 0 0 0 0

- Insulation Resistance

- > 100 MOhm 500 V DC IEC 60255-27

- US Rated Supply Voltage

- AC/DC

- , self-powered

- Connections Terminals

- screw terminals, 2 x 0.5...2 x 2.5 mm² AWG 20...AWG 14) solid without cable end

- screw terminals, 2 x 0.2...2 x 1.5 mm² AWG 24...AWG 16) flexible with cable end

- screw terminals, 1 x 0.5...1 x 3.3 mm² AWG 20...AWG 12) solid without cable end

- screw terminals, 1 x 0.2...1 x 2.5 mm² AWG 24...AWG 14) flexible with cable end

- Overvoltage Category

- III conforming to IEC 60664-1

- III conforming to UL 508

- Mounting Support

- 35 mm DIN rail conforming to IEC 60715

- CAD

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-back.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-back.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-bottom.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-bottom.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-front.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-front.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-isometric.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-isometric.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-left.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-left.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-right.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-right.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-top.dwg

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23_2D-top.dxf

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33_3DCAD&p_File_name=RM22TU23.STEP

- https://download.schneider-electric.com/files?p_Doc_Ref=RM22TA33-3d

- Supply Voltage Limits

- 304-576 V AC

- IP Degree Of Protection

- IP20 IEC 60529 terminals)

- IP40 IEC 60529 housing)

- IP50 IEC 60529 front panel)

- Prop 65

- WARNING: This product can expose you to chemicals including: Lead and lead compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Carbon Footprint Of The Installation Phase A5

- 0 kg CO2 eq.

- 0.0004490264

- Voltage Range

- 380...480 V phase to phase

- Switching Threshold Drift

- <= 0.05 % per degree centigrade depending permissible ambient air temperature

- <= 1 % within the supply voltage range

- Carbon Footprint Of The End Of Life Phase C1 To C4

- 0.0522965455

- 0.1 kg CO2 eq.

- Voltage Detection Threshold

- < 100 V AC

- Status Led

- LED (Yellow) relay ON

- LED (Green) power ON

- Maximum Switching Voltage

- 250 V AC

- Dielectric Test Voltage

- 2.5 kV AC 50 Hz, 1 min IEC 60255-27

- Maximum Measuring Cycle

- 150 ms measurement cycle as true rms value

- Carbon Footprint Of The Manufacturing Phase A1 To A3

- 2 kg CO2 eq.

- 1.8499090909

- Maximum Switching Current

- 8 A AC

- Time Delay Drift

- <= 0.05 % per degree centigrade depending permissible ambient air temperature

- <= 1 % within the supply voltage range

- Time Delay Type

- adjustable 0.1...30 s, +/- 10 % of the full scale value Tt- time delay upon fault

- Measurement Range

- 380...480 V voltage AC

- Reset Time

- 1500 ms at maximum voltage

- Vibration Resistance

- 0.075 mm 10-58.1 Hz) not in operation IEC 60068-2-6

- 1 gn 10-58.1 Hz) not in operation IEC 60068-2-6

- 0.035 mm 58.1-150 Hz) in operation IEC 60068-2-6

- 0.5 gn 58.1-150 Hz) in operation IEC 60068-2-6

- Market Segmentation

- Commercial

- Industrial

- Persona Type Names

- Charge Point Operator

- End User

- Contractor

- Original Equipment Manufacturer

- OEM - Control Panelbuilder

- Panel Builder

- Electrician

- System Integrator

- IT Channel Partner

- Measurement Error

- < 1 % over the whole range with voltage variation

- < 0.05 %/°C with temperature variation

- Power Consumption In VA

- 15-15 VA 480 V AC 60 Hz

- Carbon Footprint Of The Use Phase B2 B3 B4 B6

- 93 kg CO2 eq.

- 92.70576

- Electromagnetic Compatibility

- immunity for residential, commercial and light-industrial environments conforming to IEC 61000-6-1

- immunity for industrial environments conforming to IEC 61000-6-2

- emission standard for residential, commercial and light-industrial environments conforming to IEC 61000-6-3

- emission standard for industrial environments conforming to IEC 61000-6-4

- electrostatic discharge - test level: 6 kV level 3 (contact discharge) conforming to IEC 61000-4-2

- electrostatic discharge - test level: 8 kV level 3 (air discharge) conforming to IEC 61000-4-2

- radiated radio-frequency electromagnetic field immunity test - test level: 10 V/m level 3 conforming to IEC 61000-4-3

- electrical fast transient/burst immunity test - test level: 4 kV level 4 (direct) conforming to IEC 61000-4-4

- electrical fast transient/burst immunity test - test level: 2 kV level 4 (capacitive coupling) conforming to IEC 61000-4-4

- surge immunity test - test level: 4 kV level 4 (common mode) conforming to IEC 61000-4-5

- surge immunity test - test level: 2 kV level 4 (differential mode) conforming to IEC 61000-4-5

- conducted and radiated emissions class B group 1 conforming to CISPR 11

- conducted and radiated emissions class B conforming to CISPR 22

- Supply Frequency

- 50...60 Hz +/- 10 %

- Hysteresis

- 2-2 % fixed selectable

- Relative Humidity

- 93-97 % 25-55 °C IEC 60068-2-30

- Persona Type Ids

- BM9

- EU

- LC

- OM

- OM8

- PB

- SC

- SI

- VR

- Relay Monitored Parameters

- phase sequence

- phase failure detection

- asymmetry

- Carbon Footprint Of The Distribution Phase A4

- 0.0116116364

- 0 kg CO2 eq.

- Tightening Torque

- 0.6-1 N.m IEC 60947-1

- Minimum Switching Current

- 10 mA 5 V DC

- Repeat Accuracy

- +/- 0.5 % input and measurement circuit

- +/- 3 % time delay

- Utilisation Category

- AC-15 IEC 60947-5-1

- DC-13 IEC 60947-5-1

- AC-1 IEC 60947-4-1

- DC-1 IEC 60947-4-1

- Market Segmentation Id

- COMMERCIAL

- INDUSTRIAL

- Shock Resistance

- 15 gn 11 ms) not in operation IEC 60068-2-27

- 5 gn 11 ms) in operation IEC 60068-2-27

- Ambient Air Temperature For Operation

- -20-50 °C 60 Hz

- -20-60 °C 50 Hz AC/DC

- Complementary Attributes

- Control Circuit Voltage Limits : - 20 % + 20 % Un

- Important Information Attributes

- Local Data Status : Publishable

- Local Publishable Date : 2025-08-18

- HTML Description : Zelio Control RelayNetwork Number of Phases: 3 PhasesRelay Monitored Parameters: Asymmetry, Phase failure detection, Phase sequence Measurement Range: 380-480V ACMaximum Switching Voltage: 250V ACMaximum Switching Current: 8A ACRated Supply Voltage: 380-480V ACOutput Contacts: 2 C/OMounting Position: AnyConnections - Terminals: Screw terminalsStatus LED: LED yellow for relay ON, LED green for power ONDegree of Protection: IP20 on terminals, IP40 on housing, IP50 on front panel, conforming to IEC 60529

- Manufacturer : Schneider Electric

- Manufacturing Carbon Footprint : 1.8499090909

- Distribution Carbon Footprint : 0.0116116364

- Installation Carbon Footprint : 0.0004490264

- Use Carbon Footprint : 92.70576

- End Of Life Carbon Footprint : 0.0522965455

- Legacy WEEE Scope : Out

- WEEE Product Category : 5

- Scope Perimeter : At least in Europe

- EOLI Availability Display : Yes

- End Of Life Doc Ref : ENVEOLI2506066EN

- Reach Full Compliance Status : Reference contains Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : CONTAINS_SVHC

- Reach Compliance Directive : Reference contains Substances of Very High Concern above the threshold

- ROHS EUR In Scope : No

- ROHS EUR Status : Compliant with Exemptions

- ROHS EUR Conformity Date : 1918

- ROHS EUR Full Compliance Status : Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS EUR Full Compliance Status Id : PRO_ACTIVE_COMPLIANCE

- China ROHS In Scope : Yes

- China ROHS Label : 5

- Green Premium Status For Reporting : Green Premium product

- With Recycled Cardboard : Yes

- Without Single Use Plastic : Yes

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : Y

- WD Status : 1 - GSC certified

- Tier Id : 1

- Tier : 1

- Function Option Id : STANDARD

- Function Option : Standard

- Adjustment Of Asymmetry Threshold : 5...15 % of Un selected

- Compatibility Code : RM22

- Housing Material : self-extinguishing plastic

- Immunity To Microbreaks : 10 ms

- Package Weight Lbs : 104.0 g

- Product Availability : Stock - Normally stocked in distribution facility

- Product Or Component Type : 3-phase control relay

- Range Of Product : Harmony Control Relays

- Relay Name : RM22TA

- Response Time : <= 300 ms

- Returnability : Yes

- Setting Accuracy Of The Switching Threshold : +/- 10 % of the full scale

- Sustainable Packaging : Yes

- Total Lifecycle Carbon Footprint : 95 kg CO2 eq.

- Carbon Footprint Kg Co2 Eq Total Life Cycle : 94.6200262991

- Relationship Type : cross-selling relationship

- Pep Code : ENVPEP2506066EN

- Pep Verification Date : 2019-05-01

- PCR Version : PCR-ed3-EN-2015 04 02

- PSR Version : PSR-0005-ed2-EN-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- Product Weight In G : 90

- Functional Unit Description : To switch ON/OFF electrical contacts when the abnormal operating conditions is detected during 10 years and a 100% use rate.

- Functional Unit Quantity : 1

- Functional Unit Unit : unité (unit)

- Reference Lifetime In Y : 10

- Energy Consumption On Product Lifetime In Kwh : 189.216

- Nbr Of Units In Pkg : 1

- Warranty In Months : 18

- Energy Model Manufacturing A1 A3 : Energy model used: Indonesia

- Energy Model Installation A5 : Electricity mix; AC; < 1kV; EU-27

- Energy Model Use B6 : Electricity mix; AC; < 1kV; EU-27

- Energy Model End Of Life C1 C4 : Electricity mix; AC; < 1kV; EU-27

- Components For Re Use Kg Total Life Cycle : 0

- Components For Re Use Kg Manufacturing A1 A3 : 0

- Components For Re Use Kg Distribution A4 : 0

- Components For Re Use Kg Installation A5 : 0

- Components For Re Use Kg Operational Energy Use B6 : 0

- Components For Re Use Kg End Of Life C1 C4 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Total Life Cycle : 0.0005895295

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Manufacturing A1 A3 : 0.0005814736

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Distribution A4 : 0.0000000005

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Installation A5 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Operational Energy Use B6 : 0.0000080551

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb End Of Life C1 C4 : 0.0000000003

- Depletion Of Abiotic Resources Fossil Fuels Mj Total Life Cycle : 1071.2259531

- Depletion Of Abiotic Resources Fossil Fuels Mj Manufacturing A1 A3 : 18.6430909091

- Depletion Of Abiotic Resources Fossil Fuels Mj Distribution A4 : 0.1631372727

- Depletion Of Abiotic Resources Fossil Fuels Mj Installation A5 : 0.0058212818

- Depletion Of Abiotic Resources Fossil Fuels Mj Operational Energy Use B6 : 1052.28

- Depletion Of Abiotic Resources Fossil Fuels Mj End Of Life C1 C4 : 0.1339036364

- Exported Energy Mj By Energy Vector Total Life Cycle : 0.0000262288

- Exported Energy Mj By Energy Vector Manufacturing A1 A3 : 0.0000024655

- Exported Energy Mj By Energy Vector Distribution A4 : 0

- Exported Energy Mj By Energy Vector Installation A5 : 0.0000237633

- Exported Energy Mj By Energy Vector Operational Energy Use B6 : 0

- Exported Energy Mj By Energy Vector End Of Life C1 C4 : 0

- Hazardous Waste Disposed Of Kg Total Life Cycle : 2.525850742

- Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 2.3016272727

- Hazardous Waste Disposed Of Kg Distribution A4 : 0

- Hazardous Waste Disposed Of Kg Installation A5 : 0.0000000221

- Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 0.04833072

- Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.1758927273

- Materials For Energy Recovery Kg Total Life Cycle : 0.013761827

- Materials For Energy Recovery Kg Manufacturing A1 A3 : 0.0000000088

- Materials For Energy Recovery Kg Distribution A4 : 0

- Materials For Energy Recovery Kg Installation A5 : 0

- Materials For Energy Recovery Kg Operational Energy Use B6 : 0

- Materials For Energy Recovery Kg End Of Life C1 C4 : 0.0137618182

- Materials For Recycling Kg Total Life Cycle : 0.0347157818

- Materials For Recycling Kg Manufacturing A1 A3 : 0.0064508727

- Materials For Recycling Kg Distribution A4 : 0

- Materials For Recycling Kg Installation A5 : 0.0082546364

- Materials For Recycling Kg Operational Energy Use B6 : 0

- Materials For Recycling Kg End Of Life C1 C4 : 0.0200102727

- Net Use Of Fresh Water M3 Total Life Cycle : 336.1495975079

- Net Use Of Fresh Water M3 Manufacturing A1 A3 : 0.0103688182

- Net Use Of Fresh Water M3 Distribution A4 : 0.0000010393

- Net Use Of Fresh Water M3 Installation A5 : 0.0000000491

- Net Use Of Fresh Water M3 Operational Energy Use B6 : 336.1392

- Net Use Of Fresh Water M3 End Of Life C1 C4 : 0.0000276014

- Non Hazardous Waste Disposed Of Kg Total Life Cycle : 346.1745206569

- Non Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 0.5303945455

- Non Hazardous Waste Disposed Of Kg Distribution A4 : 0.0004125764

- Non Hazardous Waste Disposed Of Kg Installation A5 : 0.0000609496

- Non Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 345.6432

- Non Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.0004525855

- Ozone Depletion Kg Equivalent Cfc 11 Total Life Cycle : 0.0000062374

- Ozone Depletion Kg Equivalent Cfc 11 Manufacturing A1 A3 : 0.0000001963

- Ozone Depletion Kg Equivalent Cfc 11 Distribution A4 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Installation A5 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Operational Energy Use B6 : 0.0000060392

- Ozone Depletion Kg Equivalent Cfc 11 End Of Life C1 C4 : 0.0000000018

- Radioactive Waste Disposed Of Kg Total Life Cycle : 0.2311722153

- Radioactive Waste Disposed Of Kg Manufacturing A1 A3 : 0.0003244827

- Radioactive Waste Disposed Of Kg Distribution A4 : 0.0000002938

- Radioactive Waste Disposed Of Kg Installation A5 : 0.000000012

- Radioactive Waste Disposed Of Kg Operational Energy Use B6 : 0.2308464

- Radioactive Waste Disposed Of Kg End Of Life C1 C4 : 0.0000010267

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 1640.3366177182

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 23.8909090909

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0.1639636364

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0.0058549909

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 1616.112

- Total Use Of Non Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0.16389

- Total Use Of Primary Energy During The Life Cycle Mj Total Life Cycle : 1876.4536396091

- Total Use Of Primary Energy During The Life Cycle Mj Manufacturing A1 A3 : 24.5675454545

- Total Use Of Primary Energy During The Life Cycle Mj Distribution A4 : 0.1641845455

- Total Use Of Primary Energy During The Life Cycle Mj Installation A5 : 0.0058641545

- Total Use Of Primary Energy During The Life Cycle Mj Operational Energy Use B6 : 1851.552

- Total Use Of Primary Energy During The Life Cycle Mj End Of Life C1 C4 : 0.1640454545

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 236.1169568872

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.6765709091

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0.0002188064

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0.0000091072

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 235.44

- Total Use Of Renewable Primary Energy Resources Primary Energy And Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0.0001580645

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 1.5098727273

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 1.5098727273

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 1638.8270722636

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 22.3813636364

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0.1639636364

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0.0058549909

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 1616.112

- Use Of Non Renewable Primary Energy Excluding Non Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0.16389

- Use Of Non Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Non Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Non Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Non Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Non Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Non Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 0.1635218182

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.1635218182

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 235.9534268872

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.5130409091

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0.0002188064

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0.0000091072

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj Operational Energy Use B6 : 235.44

- Use Of Renewable Primary Energy Excluding Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0.0001580645

- Use Of Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Secondary Materials Kg Total Life Cycle : 0.0005282264

- Use Of Secondary Materials Kg Manufacturing A1 A3 : 0.0005282264

- Use Of Secondary Materials Kg Distribution A4 : 0

- Use Of Secondary Materials Kg Installation A5 : 0

- Use Of Secondary Materials Kg Operational Energy Use B6 : 0

- Use Of Secondary Materials Kg End Of Life C1 C4 : 0

- Air Pollution M3 Total Life Cycle : 4209.9131675455

- Air Pollution M3 Manufacturing A1 A3 : 218.1109090909

- Air Pollution M3 Distribution A4 : 0.4939690909

- Air Pollution M3 Installation A5 : 0.0179075455

- Air Pollution M3 Operational Energy Use B6 : 3990.096

- Air Pollution M3 End Of Life C1 C4 : 1.1943818182

- Water Pollution M3 Total Life Cycle : 4028.3105154545

- Water Pollution M3 Manufacturing A1 A3 : 198.6054545455

- Water Pollution M3 Distribution A4 : 1.9095545455

- Water Pollution M3 Installation A5 : 0.0680972727

- Water Pollution M3 Operational Energy Use B6 : 3825.36

- Water Pollution M3 End Of Life C1 C4 : 2.3674090909

- Acidification Of Soil And Water Kg Equivalent So2 Total Life Cycle : 0.3916959306

- Photochemical Ozone Formation Kg Equivalent C2h4 Total Life Cycle : 0.0216980733

- Water Eutrophication Kg Equivalent P04 3 Total Life Cycle : 0.0253609026

- Acidification Of Soil And Water Kg Equivalent So2 Manufacturing A1 A3 : 0.0049057364

- Acidification Of Soil And Water Kg Equivalent So2 Distribution A4 : 0.000053019

- Acidification Of Soil And Water Kg Equivalent So2 Installation A5 : 0.0000018709

- Acidification Of Soil And Water Kg Equivalent So2 Operational Energy Use B6 : 0.3866976

- Acidification Of Soil And Water Kg Equivalent So2 End Of Life C1 C4 : 0.0000377043

- Global Warming Kg Equivalent Co2 Total Life Cycle : 94.6200262991

- Global Warming Kg Equivalent Co2 Manufacturing A1 A3 : 1.8499090909

- Global Warming Kg Equivalent Co2 Distribution A4 : 0.0116116364

- Global Warming Kg Equivalent Co2 Installation A5 : 0.0004490264

- Global Warming Kg Equivalent Co2 Operational Energy Use B6 : 92.70576

- Global Warming Kg Equivalent Co2 End Of Life C1 C4 : 0.0522965455

- Photochemical Ozone Formation Kg Equivalent C2h4 Manufacturing A1 A3 : 0.0004422518

- Photochemical Ozone Formation Kg Equivalent C2h4 Distribution A4 : 0.0000037834

- Photochemical Ozone Formation Kg Equivalent C2h4 Installation A5 : 0.0000001398

- Photochemical Ozone Formation Kg Equivalent C2h4 Operational Energy Use B6 : 0.02124864

- Photochemical Ozone Formation Kg Equivalent C2h4 End Of Life C1 C4 : 0.0000032582

- Water Eutrophication Kg Equivalent P04 3 Manufacturing A1 A3 : 0.0019827

- Water Eutrophication Kg Equivalent P04 3 Distribution A4 : 0.0000122114

- Water Eutrophication Kg Equivalent P04 3 Installation A5 : 0.0000004547

- Water Eutrophication Kg Equivalent P04 3 Operational Energy Use B6 : 0.02334816

- Water Eutrophication Kg Equivalent P04 3 End Of Life C1 C4 : 0.0000173765

- General Attributes

- Product Or Component Type : 3-phase control relay

- Range Of Product : Harmony Control Relays

- Output Attributes

- Output Contacts : 2 C/O

- Environment Attributes

- ROHS Exemption Information : Yes

- China ROHS url : https://checkaproduct.se.com/DistantRequestDispatcher.aspx?action=exportPdfRoHSChina&pid=421889569&lang=en-us

- Take Back : No

- Recycled Metal Content At Cr Level : 0 %

- China ROHS Regulation : X

- Mercury Free : Yes

- Carbon Footprint : 94.6200262991

- Circularity Profile : ENVEOLI2506066EN

- Environmental Disclosure : ENVPEP2506066EN

- EU ROHS Directive : Pro-active compliance (Product out of EU RoHS legal scope)

- Packaging Made With Recycled Cardboard : Yes

- Packaging Without Single Use Plastic : Yes

- Reach Regulation : Reference contains Substances of Very High Concern above the threshold

- Pep Code : ENVPEP2506066EN

- Pep Verification Date : 2019-05-01

- PCR Version : PCR-ed3-EN-2015 04 02

- PSR Version : PSR-0005-ed2-EN-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- Specifications

- Country of Origin : Indonesia