-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

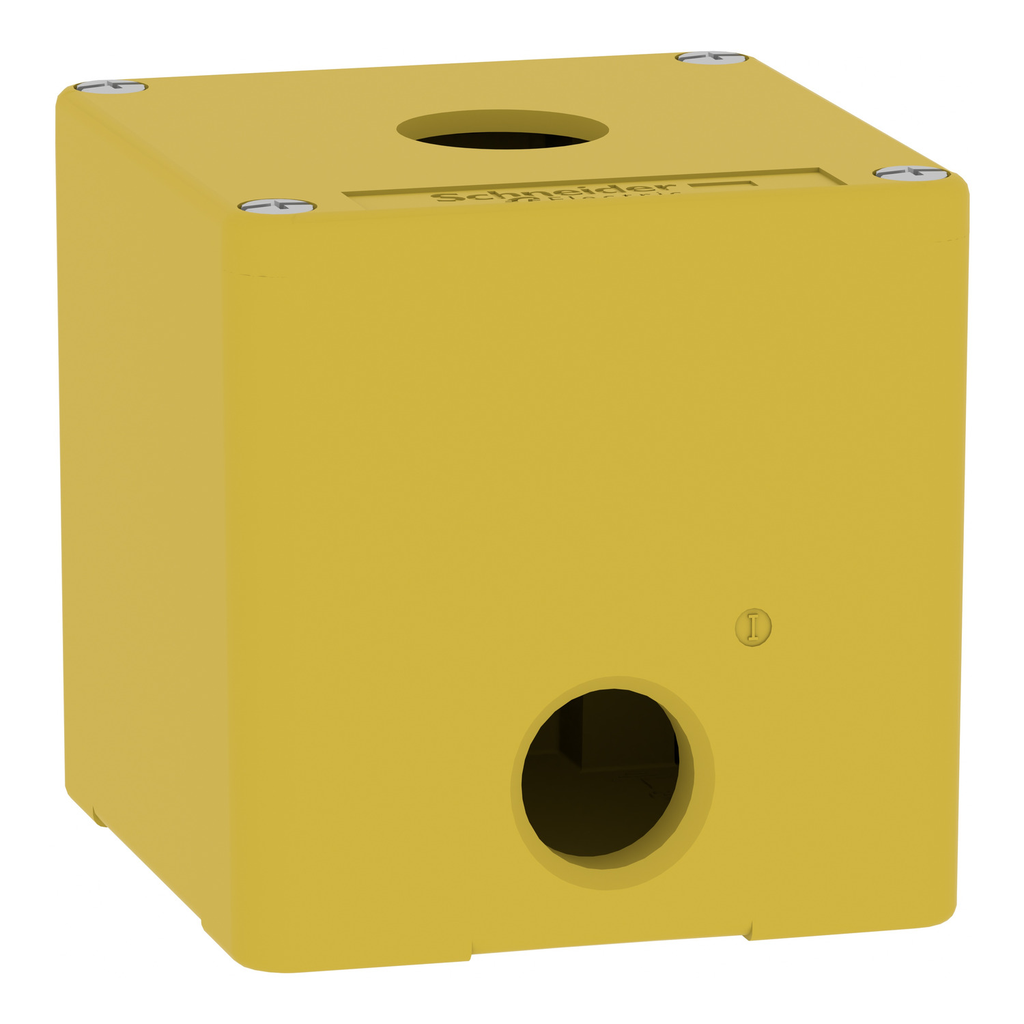

Die cast empty control station, Harmony XAP, XB2 SL, zinc alloy, yellow, M20, 1 cut out 22mm, 80x80x77mm, UL cULus

Empty control station, Harmony

SQDXAPK1501

XAPK1501

3389110001129

95.51

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-Empty-control-station-Harmony-XAP-XB2-SL-zinc-alloy-yellow-M20-1-cut-out-22mm-80x80x77mm-UL-cULus-3389110001129

This product is part of XAP range, an offer of metal control stations for XB4 and XB5 series of Ø 22mm pushbuttons. XAPK1501 is an empty enclosure for Emergency Stop with a full yellow form factor (RAL1004). This version with 1 hole allows any type of E-stops with or without legend plate. 2 sizes of legend holders can be used in different positions. Its dimension leaves a comfortable space for wiring. It is possible to customize the XAP with the Harmony online product selector and configurator. This product has been standardized with metric thread to be used with ISO cable glands to be fully compliant with the IEC 62444. It comes with two M20 holes. The electric shock protection is at class I conforming to EN/IEC 61140 and the mechanical shock protection level is up to IK07 conforming to EN/IEC 62262. This is a zinc alloy offer and the dimensions are 80mm (width) x 80mm (height) x 77mm (depth) and it weighs 0.600kg. XAPK is designed for Original Equipment Manufacturers (OEMs) that meets heavy duty application requirements such as material handling, food & beverage, wind turbines, Mining, Minerals and Metals (MMM), vehicles, etc. This enclosure complies with EN/IEC 60529 and EN/IEC 60947-5-1 and comes with CE, UL, cULus and EAC certification. Fully customized legend panel are available to improve interface experience and enclosure's aesthetic. XAP is designed to be mounted in both vertical and horizontal position with 4 fixing holes. The form factor allows a combination between simplicity, customization flexibility and attractive design for machines. It improves differentiation between standard and Emergency Stop control station.

- 0oJQOQfdUIw?si=q4JKccI4YbsRynMMIDSIG_PROMO_VIDEO_10_EN(Video)

- 6InIGoSstdc?si=2JDJpHCKfhX2BjvnIDSIG_HOW_TO_VIDEO_032_EN(Video)

- fbd5da3ec854adcf2a392a6f913d84015005915afiles?p_Doc_Ref=DIA5ED2130511EN(Download)

- d1b172ccb11b95ef807aba1e61acc855996d0abdfiles?p_Doc_Ref=CSA-80078476(Download)

- 2f9f4b4a5052012e7b6818files?p_Doc_Ref=UL-E164353-20210330&p_File_name=E39281-Vol8-Sec66-20250306.pdf(Download)

- 69c4c98e4edc9061f70fceaee1export_RohsChina_20251213_00531153d26a07d9-0377-4e43-b693-758373375d58.pdf(Download)

- 4eeaca21cee538443a4ca8b52b32db00ca130files?p_Doc_Ref=ENVPEP2309042EN&p_File_name=ENVPEP2309042EN.pdf(Download)

- 21d707936719001d52fe32ea59d6ffc0a03bcd88XAPK1501(Download)

- 21bb6d59411d556c1fd8d941413f167fd3d89e8dfiles?p_Doc_Ref=NNZ4923400(Download)

- 85ba7a91b9ddbfiles?p_Doc_Ref=eTechPub Harmony XAP_XB2 SL V1 EN&p_File_name=BU_AUT_662_EPDS_V2_EN.zip(Download)

- 82b648fbf32f31740dc5f888c79539e807c58files?p_Doc_Ref=XAPK1501-3dCAD&p_File_name=XAPK1501_2D-back.DWG(Download)

- Product Description

- Features

- Specifications

This product is part of XAP range, an offer of metal control stations for XB4 and XB5 series of Ø 22mm pushbuttons. XAPK1501 is an empty enclosure for Emergency Stop with a full yellow form factor (RAL1004). This version with 1 hole allows any type of E-stops with or without legend plate. 2 sizes of legend holders can be used in different positions. Its dimension leaves a comfortable space for wiring. It is possible to customize the XAP with the Harmony online product selector and configurator. This product has been standardized with metric thread to be used with ISO cable glands to be fully compliant with the IEC 62444. It comes with two M20 holes. The electric shock protection is at class I conforming to EN/IEC 61140 and the mechanical shock protection level is up to IK07 conforming to EN/IEC 62262. This is a zinc alloy offer and the dimensions are 80mm (width) x 80mm (height) x 77mm (depth) and it weighs 0.600kg. XAPK is designed for Original Equipment Manufacturers (OEMs) that meets heavy duty application requirements such as material handling, food & beverage, wind turbines, Mining, Minerals and Metals (MMM), vehicles, etc. This enclosure complies with EN/IEC 60529 and EN/IEC 60947-5-1 and comes with CE, UL, cULus and EAC certification. Fully customized legend panel are available to improve interface experience and enclosure's aesthetic. XAP is designed to be mounted in both vertical and horizontal position with 4 fixing holes. The form factor allows a combination between simplicity, customization flexibility and attractive design for machines. It improves differentiation between standard and Emergency Stop control station.

- Prop 65

- WARNING: This product can expose you to chemicals including: Lead and lead compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Physical Attributes

- Color Of Base Of Enclosure : yellow RAL 1004), yellow RAL 1004)

- Color Of Cover : yellow RAL 1004), yellow RAL 1004)

- Cad Overall Depth : 77 mm

- Cad Overall Height : 80 mm

- Cad Overall Width : 80 mm

- Product Front Plate Size : 80 x 80 mm

- Usable Depth : 74.5 mm

- Environment Attributes Additional

- Energy Model Manufacturing A1 A3 : Energy model used: France

- Energy Model Installation A5 : Electricity mix; AC; 120V; US

- Energy Model Use B6 : Electricity mix; AC; 120V; US

- Energy Model End Of Life C1 C4 : Electricity mix; AC; 120V; US

- Components For Re Use Kg Total Life Cycle : 0

- Components For Re Use Kg Manufacturing A1 A3 : 0

- Components For Re Use Kg Distribution A4 : 0

- Components For Re Use Kg Installation A5 : 0

- Components For Re Use Kg Operational Energy Use B6 : 0

- Components For Re Use Kg End Of Life C1 C4 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Total Life Cycle : 0.0003313488

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Manufacturing A1 A3 : 0.0003313439

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Distribution A4 : 0.0000000031

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Installation A5 : 0.0000000001

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb Operational Energy Use B6 : 0

- Depletion Of Abiotic Resources Elements Kg Equivalent Sb End Of Life C1 C4 : 0.0000000017

- Depletion Of Abiotic Resources Fossil Fuels Mj Total Life Cycle : 56.9556835979

- Depletion Of Abiotic Resources Fossil Fuels Mj Manufacturing A1 A3 : 55.180952381

- Depletion Of Abiotic Resources Fossil Fuels Mj Distribution A4 : 1.0876190476

- Depletion Of Abiotic Resources Fossil Fuels Mj Installation A5 : 0.0235989418

- Depletion Of Abiotic Resources Fossil Fuels Mj Operational Energy Use B6 : 0

- Depletion Of Abiotic Resources Fossil Fuels Mj End Of Life C1 C4 : 0.6635132275

- Exported Energy Mj By Energy Vector Total Life Cycle : 0.0027433111

- Exported Energy Mj By Energy Vector Manufacturing A1 A3 : 0.0026469841

- Exported Energy Mj By Energy Vector Distribution A4 : 0

- Exported Energy Mj By Energy Vector Installation A5 : 0.000096327

- Exported Energy Mj By Energy Vector Operational Energy Use B6 : 0

- Exported Energy Mj By Energy Vector End Of Life C1 C4 : 0

- Hazardous Waste Disposed Of Kg Total Life Cycle : 1.6497990318

- Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 0.9088888889

- Hazardous Waste Disposed Of Kg Distribution A4 : 0

- Hazardous Waste Disposed Of Kg Installation A5 : 0.00000009

- Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 0

- Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.7409100529

- Materials For Energy Recovery Kg Total Life Cycle : 0.0002758307

- Materials For Energy Recovery Kg Manufacturing A1 A3 : 0

- Materials For Energy Recovery Kg Distribution A4 : 0

- Materials For Energy Recovery Kg Installation A5 : 0

- Materials For Energy Recovery Kg Operational Energy Use B6 : 0

- Materials For Energy Recovery Kg End Of Life C1 C4 : 0.0002758307

- Materials For Recycling Kg Total Life Cycle : 0.4871502646

- Materials For Recycling Kg Manufacturing A1 A3 : 0.0593068783

- Materials For Recycling Kg Distribution A4 : 0

- Materials For Recycling Kg Installation A5 : 0.0334624339

- Materials For Recycling Kg Operational Energy Use B6 : 0

- Materials For Recycling Kg End Of Life C1 C4 : 0.3943809524

- Net Use Of Fresh Water M3 Total Life Cycle : 0.0633601664

- Net Use Of Fresh Water M3 Manufacturing A1 A3 : 0.0632878307

- Net Use Of Fresh Water M3 Distribution A4 : 0.0000069281

- Net Use Of Fresh Water M3 Installation A5 : 0.0000001991

- Net Use Of Fresh Water M3 Operational Energy Use B6 : 0

- Net Use Of Fresh Water M3 End Of Life C1 C4 : 0.0000652085

- Non Hazardous Waste Disposed Of Kg Total Life Cycle : 0.4217558413

- Non Hazardous Waste Disposed Of Kg Manufacturing A1 A3 : 0.4162222222

- Non Hazardous Waste Disposed Of Kg Distribution A4 : 0.0027504762

- Non Hazardous Waste Disposed Of Kg Installation A5 : 0.000248328

- Non Hazardous Waste Disposed Of Kg Operational Energy Use B6 : 0

- Non Hazardous Waste Disposed Of Kg End Of Life C1 C4 : 0.0025348148

- Ozone Depletion Kg Equivalent Cfc 11 Total Life Cycle : 0.00000087

- Ozone Depletion Kg Equivalent Cfc 11 Manufacturing A1 A3 : 0.0000008661

- Ozone Depletion Kg Equivalent Cfc 11 Distribution A4 : 0.0000000002

- Ozone Depletion Kg Equivalent Cfc 11 Installation A5 : 0

- Ozone Depletion Kg Equivalent Cfc 11 Operational Energy Use B6 : 0

- Ozone Depletion Kg Equivalent Cfc 11 End Of Life C1 C4 : 0.0000000037

- Radioactive Waste Disposed Of Kg Total Life Cycle : 0.0001423698

- Radioactive Waste Disposed Of Kg Manufacturing A1 A3 : 0.0001364021

- Radioactive Waste Disposed Of Kg Distribution A4 : 0.0000019589

- Radioactive Waste Disposed Of Kg Installation A5 : 0.0000000486

- Radioactive Waste Disposed Of Kg Operational Energy Use B6 : 0

- Radioactive Waste Disposed Of Kg End Of Life C1 C4 : 0.0000039601

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj TLC : 75.9396402116

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Mfg A1 A3 : 73.9978835979

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Dist A4 : 1.0931216931

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj Inst A5 : 0.0237354497

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Total Use Of NRE PrE Resources And PrE Resources Used As RawMats Mj EoL C1 C4 : 0.8248994709

- Total Use Of Primary Energy During The Life Cycle Mj Total Life Cycle : 76.2807037037

- Total Use Of Primary Energy During The Life Cycle Mj Manufacturing A1 A3 : 74.3365079365

- Total Use Of Primary Energy During The Life Cycle Mj Distribution A4 : 1.0946031746

- Total Use Of Primary Energy During The Life Cycle Mj Installation A5 : 0.0237724868

- Total Use Of Primary Energy During The Life Cycle Mj Operational Energy Use B6 : 0

- Total Use Of Primary Energy During The Life Cycle Mj End Of Life C1 C4 : 0.8258201058

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj TLC : 0.3409248815

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Mfg A1 A3 : 0.3385079365

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Dist A4 : 0.0014587302

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj Inst A5 : 0.0000369556

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Total Use Of RE PrE Resources And PrE Resources Used As RawMats Mj EoL C1 C4 : 0.0009212593

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 0.1634920635

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.1634920635

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of NRE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of Non Renewable Primary Energy Resources Used As Raw Materials Mj End Of Life C1 C4 : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj TLC : 75.7766772487

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Mfg A1 A3 : 73.8349206349

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Dist A4 : 1.0931216931

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj Inst A5 : 0.0237354497

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of NRE PrE Excluding NRE PrE Resources Used As RawMats Mj EoL C1 C4 : 0.8248994709

- Use Of Non Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Non Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Non Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Non Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Non Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Non Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Total Life Cycle : 0.1645396825

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Manufacturing A1 A3 : 0.1645396825

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Distribution A4 : 0

- Use Of Renewable Primary Energy Resources Used As Raw Materials Mj Installation A5 : 0

- Use Of RE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of RE PrE Resources Used As RawMats Mj BLB SysBound D : 0

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj TLC : 0.1763746169

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Mfg A1 A3 : 0.173957672

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Dist A4 : 0.0014587302

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj Inst A5 : 0.0000369556

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj OpEnergy B6 : 0

- Use Of RE PrE Excluding RE PrE Resources Used As RawMats Mj EoL C1 C4 : 0.0009212593

- Use Of Renewable Secondary Fuels Mj Total Life Cycle : 0

- Use Of Renewable Secondary Fuels Mj Manufacturing A1 A3 : 0

- Use Of Renewable Secondary Fuels Mj Distribution A4 : 0

- Use Of Renewable Secondary Fuels Mj Installation A5 : 0

- Use Of Renewable Secondary Fuels Mj Operational Energy Use B6 : 0

- Use Of Renewable Secondary Fuels Mj End Of Life C1 C4 : 0

- Use Of Secondary Materials Kg Total Life Cycle : 0.0274359788

- Use Of Secondary Materials Kg Manufacturing A1 A3 : 0.0274359788

- Use Of Secondary Materials Kg Distribution A4 : 0

- Use Of Secondary Materials Kg Installation A5 : 0

- Use Of Secondary Materials Kg Operational Energy Use B6 : 0

- Use Of Secondary Materials Kg End Of Life C1 C4 : 0

- Air Pollution M3 Total Life Cycle : 3383.1785333333

- Air Pollution M3 Manufacturing A1 A3 : 3373.9682539683

- Air Pollution M3 Distribution A4 : 3.2931216931

- Air Pollution M3 Installation A5 : 0.0726074074

- Air Pollution M3 Operational Energy Use B6 : 0

- Air Pollution M3 End Of Life C1 C4 : 5.8445502646

- Water Pollution M3 Total Life Cycle : 348.0554179894

- Water Pollution M3 Manufacturing A1 A3 : 328.7830687831

- Water Pollution M3 Distribution A4 : 12.7301587302

- Water Pollution M3 Installation A5 : 0.2760529101

- Water Pollution M3 Operational Energy Use B6 : 0

- Water Pollution M3 End Of Life C1 C4 : 6.2661375661

- Acidification Of Soil And Water Kg Equivalent So2 Total Life Cycle : 0.0093569602

- Photochemical Ozone Formation Kg Equivalent C2h4 Total Life Cycle : 0.0005931288

- Water Eutrophication Kg Equivalent P04 3 Total Life Cycle : 0.0024185919

- Acidification Of Soil And Water Kg Equivalent So2 Manufacturing A1 A3 : 0.0088312169

- Acidification Of Soil And Water Kg Equivalent So2 Distribution A4 : 0.0003534603

- Acidification Of Soil And Water Kg Equivalent So2 Installation A5 : 0.0000075846

- Acidification Of Soil And Water Kg Equivalent So2 Operational Energy Use B6 : 0

- Acidification Of Soil And Water Kg Equivalent So2 End Of Life C1 C4 : 0.0001646984

- Global Warming Kg Equivalent Co2 Total Life Cycle : 4.4654393651

- Global Warming Kg Equivalent Co2 Manufacturing A1 A3 : 4.3322751323

- Global Warming Kg Equivalent Co2 Distribution A4 : 0.0774137566

- Global Warming Kg Equivalent Co2 Installation A5 : 0.0018203175

- Global Warming Kg Equivalent Co2 Operational Energy Use B6 : 0

- Global Warming Kg Equivalent Co2 End Of Life C1 C4 : 0.0539301587

- Photochemical Ozone Formation Kg Equivalent C2h4 Manufacturing A1 A3 : 0.0005496614

- Photochemical Ozone Formation Kg Equivalent C2h4 Distribution A4 : 0.0000252233

- Photochemical Ozone Formation Kg Equivalent C2h4 Installation A5 : 0.0000005669

- Photochemical Ozone Formation Kg Equivalent C2h4 Operational Energy Use B6 : 0

- Photochemical Ozone Formation Kg Equivalent C2h4 End Of Life C1 C4 : 0.0000176772

- Water Eutrophication Kg Equivalent P04 3 Manufacturing A1 A3 : 0.0022964021

- Water Eutrophication Kg Equivalent P04 3 Distribution A4 : 0.0000814116

- Water Eutrophication Kg Equivalent P04 3 Installation A5 : 0.0000018437

- Water Eutrophication Kg Equivalent P04 3 Operational Energy Use B6 : 0

- Water Eutrophication Kg Equivalent P04 3 End Of Life C1 C4 : 0.0000389344

- Important Information Attributes

- Persona Type Ids : BM9, EU, LC, OM, OM8, PB, SC, SI, VR

- Persona Type Names : Charge Point Operator, End User, Contractor, Original Equipment Manufacturer, OEM - Control Panelbuilder, Panel Builder, Electrician, System Integrator, IT Channel Partner

- Market Segmentation Id : COMMERCIAL, INDUSTRIAL

- Market Segmentation : Commercial, Industrial

- Cable Entry : 2 x cable gland ISO, 2 x cable gland ISO, 2 x cable gland ISO

- Color Of Base Of Enclosure : yellow RAL 1004), yellow RAL 1004)

- Color Of Cover : yellow RAL 1004), yellow RAL 1004)

- Electrical Shock Protection Class : class I conforming to IEC 61140, class I conforming to IEC 61140

- Local Data Status : Publishable

- Local Publishable Date : 2025-11-25

- Legacy WEEE Scope : Out

- Scope Perimeter : At least in Europe

- EOLI Availability Display : No need of specific recycling operations

- Reach Full Compliance Status : Free of Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : NOT_CONTAINING_SVHC

- Reach Compliance Directive : Free of Substances of Very High Concern above the threshold

- ROHS EUR In Scope : No

- ROHS EUR Status : Compliant

- ROHS EUR Full Compliance Status : Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS EUR Full Compliance Status Id : PRO_ACTIVE_COMPLIANCE

- China ROHS In Scope : Yes

- Green Premium Status For Reporting : Green Premium product

- With Recycled Cardboard : Yes

- Without Single Use Plastic : Yes

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : Y

- WD Status : 1 - GSC certified

- Function Option Id : STANDARD

- Function Option : Standard

- Control Station Type : metal

- Device Short Name : XAPK

- Package Weight Lbs : 786.000 g

- Product Availability : Non-Stock - Not normally stocked in distribution facility

- Product Or Component Type : die-cast empty control station

- Range Of Product : Harmony XAP

- Resistance To Chemical Agents : special treatment can be obtained on request

- Returnability : Yes

- Sustainable Packaging : Yes

- Thread Type : M20 x 1.5

- Total Lifecycle Carbon Footprint : 4 kg CO2 eq.

- Relationship Type : Compatible relationship

- Pep Code : ENVPEP2309042EN

- Pep Verification Date : 2021-12-01

- PCR Version : PCR-ed3-EN-2015 04 02

- PSR Version : PSR-0005-ed2-EN-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- Functional Unit Description : The main function of XAP control station box is to provide complete water tight connection for XB4 and XB5 range products during 20 years with the following dimension is 80mm x 80mm x 51mm with EN/IEC 60529 standard.

- Functional Unit Unit : Unit

- Product Kit Identifier : N

- Huella De Carbono De La Fase De Distribución A4 : 0.1 kg CO2 eq.

- Huella De Carbono De La Fase De Fabricación A1 A A3 : 4 kg CO2 eq.

- Huella De Carbono De La Fase De Fin De Vida C1 A C4 : 0.1 kg CO2 eq.

- Huella De Carbono De La Fase De Instalación A5 : 0 kg CO2 eq.

- Huella De Carbono De La Fase De Uso B2 B3 B4 B6 : 0 kg CO2 eq.

- Environment Attributes Main

- EU ROHS Directive : Compliant, Pro-active compliance (Product out of EU RoHS legal scope)

- IP Degree Of Protection : IP65 EN/IEC 60529 and EN/IEC 60947-5-1, IP65 EN/IEC 60529 and EN/IEC 60947-5-1, IP66 EN/IEC 60529 and EN/IEC 60947-5-1, IP66 EN/IEC 60529 and EN/IEC 60947-5-1, IP69 EN/IEC 60529 and EN/IEC 60947-5-1, IP69 EN/IEC 60529 and EN/IEC 60947-5-1

- ROHS Exemption Information : Yes

- Take Back : No

- Reach Free SHVC : Yes

- Recycled Metal Content At Cr Level : 0 %

- China ROHS Regulation : X

- Toxic Heavy Metal Free : Yes

- Mercury Free : Yes

- Carbon Footprint : 4.4654393651

- Environmental Disclosure : ENVPEP2309042EN

- Packaging Made With Recycled Cardboard : Yes

- Packaging Without Single Use Plastic : Yes

- Reach Free Of SVHC : Yes

- Reach Regulation : Free of Substances of Very High Concern above the threshold

- Pep Code : ENVPEP2309042EN

- Pep Verification Date : 2021-12-01

- PCR Version : PCR-ed3-EN-2015 04 02

- PSR Version : PSR-0005-ed2-EN-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- General Attributes

- Product Or Component Type : die-cast empty control station

- Range Of Product : Harmony XAP