-

{{ vm.branchName }}

-

-

-

Extended Price:{{'{0} of {1} requested items are in stock.'.replace('{0}', line.qtyOnHand).replace('{1}', vm.getSumQtyPerUom(line.productId, vm.cart.cartLines))}} Restricted product Inactive productContact Mayer for Current Price. Contact Mayer for Current Price

Out Of Stock

One or more products you added to your cart are out of stock, Please review your cart and adjust if necessary.

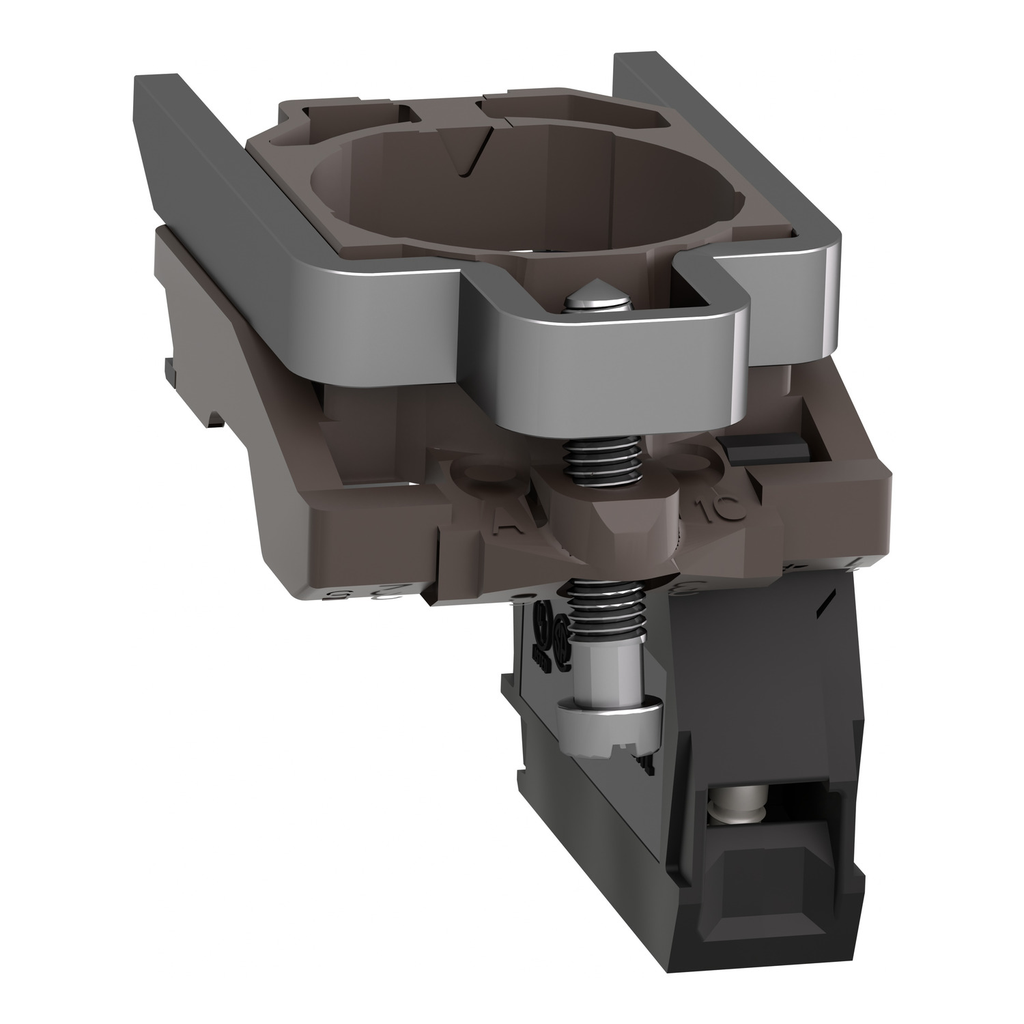

Complete body contact assembly, Harmony XB4, single contact, with body fixing collar, 1NC, set of 100

Complete body contact assembly, Harmony XB4, single contact, with body fixing collar, 1NC, set of 100

SQDZB4BZ102TQ

ZB4BZ102TQ

3389110883305

23.63

/ EA

http://schema.org/OutOfStock

/Product/SQUARE-D-Complete-body-contact-assembly-Harmony-XB4-single-contact-with-body-fixing-collar-1NC-set-of-100-785901723677

- Head Type: Standard

- Operating Force: 2 N

- Warranty Length: 18 mth

This body fixing collar is pre-mounted with a contact block Simply adding a head to this assembly will provide you with a complete ready-to-use push-button It is sold by 100 units High performance International standards & certifications (Marine ABS certification, IP66, Type 1, 2, 3, 3R, 4, 12 and 13)

- fc1109321d0af9dd5ccde106cf0f2ac67f131e13files?p_Doc_Ref=DIA4ED2060507CEN-US(Download)

- 2984ed68eead35f0da72af5008a05d04e85041c1files?p_Doc_Ref=00_00156(Download)

- c5ab05228457fba5734acadac26f1de21600c000files?p_Doc_Ref=INERIS-04IEC0002(Download)

- 90d7c549101c7b5bffc690a6ad1e1f6c5faf4d11files?p_Doc_Ref=CCC-2003010305059267(Download)

- 03658ebfe831a2d2ff0e065e2b9488efc8d18502download.zip(Download)

- 42598b7b4948a84891b9e3ca0cdb378f1f4bd108download.zip(Download)

- 7ab01c7298d2deacdb9266c2ea139f5fea93285bfiles?p_Doc_Ref=CSA-1156198(Download)

- a1406051ed3c5beed036b0797ebecb9647fa88e5files?p_Doc_Ref=DNV-GL-TAE00001C8_2017-01-22(Download)

- 9b3efd63001558bc6fd2ed87253744f752290639files?p_Doc_Ref=CB_Scheme_DK-83825-M1-UL(Download)

- bc6aa314122668db10fa0ddfiles?p_Doc_Ref=UL-E39281-19981027&p_File_name=E39281-Vol8-Sec42-20250307.pdf(Download)

- ff289d1c80e86a0e3278ef519e27120fac554be2files?p_Doc_Ref=UE-NVE6415100(Download)

- 9cb55848ec03b8a1d3b7134f1a8d0d201fbb3af3files?p_Doc_Ref=BV-09777&p_File_name=09777_E2 BV.pdf(Download)

- 94d7f2fc232e65101c91b1844453fdfc75files?p_Doc_Ref=ENVPEP2308035EN&p_File_name=ENVPEP2308035_V1_1.pdf(Download)

- 09b95b9f7e76e9a85311b40d851006a89404f813ZB4BZ102TQ(Download)

- 25b6d3ddd09cb658fc6be9ff3e2480f6ccfiles?p_Doc_Ref=ENVEOLI2308035EN&p_File_name=ENVEOLI2308035_V1.pdf(Download)

- 197c22255f477997c0files?p_Doc_Ref=UK-JYT5924200&p_File_name=UK_DoC_JYT5924200-01_XB4_XB5_XD4_XD5.pdf(Download)

- 59076e8ad7e9a4906d4e60d9665afcb2e8d25f93files?p_Doc_Ref=65013-037-26(Download)

- 9aa3641a8dbc0664869b7afe6e1f9aea01e516files?p_Doc_Ref=BRU46063&p_File_name=BRU46063_00 - XB4-XB5.pdf(Download)

- efed9e189d65a41ee0a41656a9files?p_Doc_Ref=Harmony_XB4_V14_En&p_File_name=BU_AUT_632_EPDS_V_03_EN.zip(Download)

- 5c7f313dccd20d7e29f3d212196848375d9482dbfiles?p_Doc_Ref=ZB4BZ101_NEW_2024(Download)

- fe97dead7f44d2624674d8baac9450e9ae0c547bfiles?p_Doc_Ref=ZB4BZ102TQ_3DCAD(Download)

- 1951067e703076501e00c3256b0e0fa1cb02c74dfiles?p_Doc_Ref=9001BR9401(Download)

- Product Description

- Features

- Specifications

This body fixing collar is pre-mounted with a contact block Simply adding a head to this assembly will provide you with a complete ready-to-use push-button It is sold by 100 units High performance International standards & certifications (Marine ABS certification, IP66, Type 1, 2, 3, 3R, 4, 12 and 13)

- Prop 65

- WARNING: This product can expose you to chemicals including: Di-isodecyl phthalate (DIDP), which is known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Complementary Attributes

- IE Rated Operational Current : 3 A 240 V, AC-15, A600 IEC 60947-5-1, 6 A 120 V, AC-15, A600 IEC 60947-5-1, 0.1 A 600 V, DC-13, Q600 IEC 60947-5-1, 0.27 A 250 V, DC-13, Q600 IEC 60947-5-1, 0.55 A 125 V, DC-13, Q600 IEC 60947-5-1, 1.2 A 600 V, AC-15, A600 IEC 60947-5-1

- UI Rated Insulation Voltage : 600 V 3)IEC 60947-1

- UIMP Rated Impulse Withstand Voltage : 6 kV IEC 60947-1

- Important Information Attributes

- Customizable : no, 0

- Electrical Durability : 10000000 cycles, AC-15, 2 A 230 V 3600 cyc/h 0.5 IEC 60947-5-1 appendix C, 10000000 cycles, AC-15, 3 A 120 V 3600 cyc/h 0.5 IEC 60947-5-1 appendix C, 10000000 cycles, AC-15, 4 A 24 V 3600 cyc/h 0.5 IEC 60947-5-1 appendix C, 10000000 cycles, DC-13, 0.2 A 110 V 3600 cyc/h 0.5 IEC 60947-5-1 appendix C, 10000000 cycles, DC-13, 0.5 A 24 V 3600 cyc/h 0.5 IEC 60947-5-1 appendix C

- Electrical Reliability : λ < 10exp(-6) 5 V, 1 mA in clean environment IEC 60947-5-4, λ < 10exp(-8) 17 V, 5 mA in clean environment IEC 60947-5-4

- Operating Travel : 1.5 mm NC changing electrical state), 4.3 mm total travel)

- Shape Of Screw Head : cross Philips no 1, cross pozidriv No 1, slotted flat Ø 4 mm, slotted flat Ø 5.5 mm

- Shock Resistance : 30 gn 18 ms) half sine wave acceleration IEC 60068-2-27, 50 gn 11 ms) half sine wave acceleration IEC 60068-2-27

- IE Rated Operational Current : 3 A 240 V, AC-15, A600 IEC 60947-5-1, 6 A 120 V, AC-15, A600 IEC 60947-5-1, 0.1 A 600 V, DC-13, Q600 IEC 60947-5-1, 0.27 A 250 V, DC-13, Q600 IEC 60947-5-1, 0.55 A 125 V, DC-13, Q600 IEC 60947-5-1, 1.2 A 600 V, AC-15, A600 IEC 60947-5-1

- Carbon Footprint Of The Distribution Phase A4 : 0.0061462396, 0 kg CO2 eq.

- Carbon Footprint Of The End Of Life Phase C1 To C4 : 0.1 kg CO2 eq., 0.0594497034

- Carbon Footprint Of The Installation Phase A5 : 0.0094267616, 0 kg CO2 eq.

- Carbon Footprint Of The Manufacturing Phase A1 To A3 : 0.3 kg CO2 eq., 0.3331368921

- Carbon Footprint Of The Use Phase B2 B3 B4 B6 : 0 kg CO2 eq., 0.026093662

- Connections Terminals : screw clamp terminals, <= 2 x 1.5 mm² with cable end IEC 60947-1, screw clamp terminals, >= 1 x 0.22 mm² without cable end IEC 60947-1

- Local Data Status : Publishable

- Local Publishable Date : 2026-01-12

- Legacy WEEE Scope : In

- Scope Perimeter : At least in Europe

- EOLI Availability Display : Yes

- End Of Life Doc Ref : ENVEOLI2308035EN

- Reach Full Compliance Status : Free of Substances of Very High Concern above the threshold

- Reach Full Compliance Status Id : NOT_CONTAINING_SVHC

- Reach Compliance Directive : Free of Substances of Very High Concern above the threshold

- ROHS EUR In Scope : No

- ROHS EUR Status : Compliant

- ROHS EUR Full Compliance Status : Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS EUR Full Compliance Status Id : PRO_ACTIVE_COMPLIANCE

- China ROHS In Scope : Yes

- Green Premium Status For Reporting : Green Premium product

- With Recycled Cardboard : Yes

- Without Single Use Plastic : No

- Product Contributes To Saved And Avoided Emissions : No

- Return Indicator : Y

- WD Status : 1 - GSC certified

- Average Percentage Of Recycled Metal Content : 16 %

- Average Percentage Of Recycled Plastic Content : 23 %

- Compatibility Code : ZB4

- Contact Block Type : single

- Contacts Usage : standard contacts

- Device Short Name : ZB4

- Fixing Collar Material : zamak

- Head Type : standard

- Operating Force : 2 N NC changing electrical state

- Package Weight Lbs : 47.000 g

- Positive Opening : with IEC 60947-5-1 appendix K

- Product Availability : Stock - Normally stocked in distribution facility

- Product Or Component Type : complete body/contact assembly

- Range Of Product : Harmony XB4

- Returnability : Yes

- Short Circuit Protection : 10 A cartridge fuse gG IEC 60947-5-1

- Sustainable Packaging : No

- Tightening Torque : 0.8-1.2 N.m IEC 60947-1

- Total Lifecycle Carbon Footprint : 0.4 kg CO2 eq.

- Vibration Resistance : 5 gn (f= 2-500 Hz) conforming to IEC 60068-2-6

- Weee Label : The product must be disposed on European Union markets following specific waste collection and never end up in rubbish bins.

- ITH Conventional Free Air Thermal Current : 10 A IEC 60947-5-1

- Relationship Type : Compatible relationship

- Pep Code : ENVPEP2308035_V1-EN

- Pep Verification Date : 2023-08-01

- PCR Version : PEP-PCR-ed4-2021 09 06

- PSR Version : PSR-0005-ed2-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- Functional Unit Description : This Harmony XB4 modular green push button operates with a spring return / impulse mechanism. It has a metal bezel. This push button provides an ergonomic interface for controlling your machines. It is easily installed into standard 22mm diameter panel cut-outs and connected to control circuits with classic screw-clamp connections.The main function of a push button switch is to switch something either on or off industrial applications with power consumption 0.002W with 71% active mode for 10 years and product is conforming with standard EN 60947-5-1.

- Functional Unit Unit : Unit

- Product Kit Identifier : N

- Product Manager : SU-JIN NG

- Environment Attributes Main

- EU ROHS Directive : Compliant, Pro-active compliance (Product out of EU RoHS legal scope)

- ROHS Exemption Information : Yes

- Take Back : No

- Reach Free SHVC : Yes

- Recycled Metal Content At Cr Level : 16 %

- China ROHS Regulation : X

- Toxic Heavy Metal Free : Yes

- Mercury Free : Yes

- Carbon Footprint : 0.4342532587

- Circularity Profile : ENVEOLI2308035EN

- Environmental Disclosure : ENVPEP2308035_V1-EN

- IP Degree Of Protection : IP20 IEC 60529

- Packaging Made With Recycled Cardboard : Yes

- Packaging Without Single Use Plastic : No

- Reach Free Of SVHC : Yes

- Reach Regulation : Free of Substances of Very High Concern above the threshold

- Pep Code : ENVPEP2308035_V1-EN

- Pep Verification Date : 2023-08-01

- PCR Version : PEP-PCR-ed4-2021 09 06

- PSR Version : PSR-0005-ed2-2016 03 29

- Type Of Verification For The Pep : Independent internal review

- General Attributes

- Product Or Component Type : complete body/contact assembly

- Range Of Product : Harmony XB4

- Contractual Warranty Attributes

- Warranty Period : 18 months

- Warranty : 18 months